The procurement process is the backbone of any successful business, ensuring a steady flow of goods and services at optimal costs. However, traditional methods can be bogged down by manual tasks, repetitive paperwork, and data entry errors. This not only impacts efficiency but also hinders strategic decision-making. This is where Robotic Process Automation (RPA) emerges as a revolutionary force, transforming the procurement landscape with unprecedented speed, accuracy, and cost-effectiveness.

This blog delves into the transformative power of RPA in procurement. We’ll explore key use cases and applications that streamline operations, automate repetitive tasks, free up your team’s time for strategic initiatives, and ultimately unlock new levels of efficiency and empower smarter procurement strategies.

Understanding RPA

Robotic Process Automation (RPA) is a technology rapidly transforming various industries, including procurement. It utilizes software robots to automate repetitive, rule-based tasks traditionally performed by humans interacting with digital systems. Unlike physical robots in manufacturing, these software robots, often called “bots,” exist within the digital world.

Here’s A Breakdown Of RPA’s Core Functionalities:

1. Automating Repetitive Tasks:

Data entry, form filling, file transfers, and other routine processes become automated, freeing up human capital for more strategic work.

2. Mimicking Human Actions:

RPA bots follow pre-programmed instructions to interact with various digital interfaces, replicating human actions within computer systems.

3. Rule-Based Approach:

These bots excel at tasks with well-defined steps and predictable outcomes, making them ideal for streamlining standardized processes.

RPA functions as a powerful tool that streamlines workflows, minimizes errors, and allows human staff to focus on higher-level cognitive tasks that require critical thinking, strategic decision-making, and creative problem-solving.

A prime example of RPA’s success comes from global manufacturing giant Siemens, renowned for its expertise in industrial automation. Siemens embraced RPA to streamline their procurement processes, specifically targeting bottlenecks and inaccuracies caused by manual data entry for purchase orders. They implemented RPA bots that automate the entire process. These bots extract data from supplier quotes, populate purchase orders within their ERP system, and even initiate automated approval workflows.

The results were significant – error rates plummeted, processing times for purchase orders decreased dramatically, and procurement staff were freed from the burden of tedious tasks. This newfound freedom empowered them to focus on higher-value activities like building strong supplier relationships, negotiating better contracts, and ultimately driving overall procurement efficiency.

Market Overview

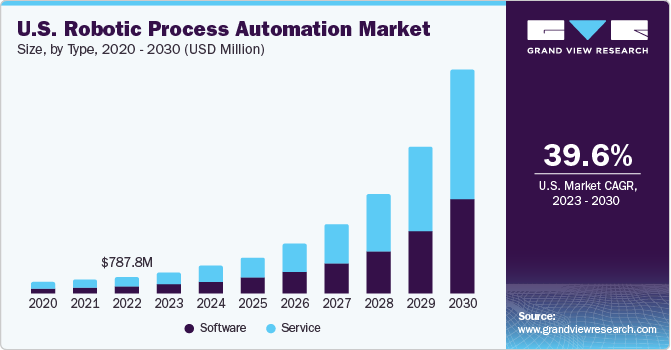

The global market for robotic process automation reached a value of USD 2,942.7 million in 2023 and is forecasted to expand at a compound annual growth rate (CAGR) of 39.9% from 2023 to 2030. RPA adoption in the manufacturing sector has evolved significantly over time and is expected to become more sophisticated during the period mentioned.

This evolution will be driven by the integration of advanced technologies such as artificial intelligence (AI), machine learning (ML), optical character recognition (OCR), and analytics with RPA, leading to enhanced performance. Intelligent automation is predicted to reduce service desk interactions by around 40% by 2025.

According to another analysis, the estimated size of the Robotic Process Automation Market was USD 4.02 billion in 2024 and is anticipated to reach USD 14.75 billion by 2029, registering a CAGR of 29.70% during the forecast period (2024-2029). Additionally, it is projected that over USD 2 trillion could be saved globally by automating nearly half of human tasks, particularly in industries like retail, which are in a stage of emergence.

Importance Of RPA In Procurement

Here’s a breakdown of the key reasons why RPA is crucial for modern procurement:

1. Enhanced Operational Efficiency:

RPA transforms procurement operations by automating repetitive tasks such as data entry, invoice processing, and purchase order generation. This automation not only accelerates processes but also ensures unmatched accuracy, liberating procurement staff from mundane tasks and enabling them to focus on strategic initiatives that drive value.

2. Error Reduction And Data Integrity:

Manual data entry is susceptible to errors, leading to delays, discrepancies, and increased costs. RPA eliminates this risk by ensuring flawless data accuracy and consistency, thereby enhancing data integrity and streamlining workflows. By minimizing errors, RPA contributes to smoother procurement processes and mitigates potential financial risks.

3. Cost Optimization:

The implementation of RPA in procurement yields significant cost savings by reducing processing times, minimizing error rates, and streamlining operations. These cost optimizations translate into financial benefits, enabling organizations to allocate resources more efficiently and invest in strategic growth initiatives.

4. Enhanced Visibility And Control:

RPA seamlessly integrates with existing procurement software, providing real-time data and insights into procurement activities. This enhanced visibility empowers stakeholders with actionable intelligence, facilitating informed decision-making and enabling proactive management of procurement processes. It allows better control over procurement operations and allows organizations to identify opportunities for cost optimization and supplier performance improvement.

5. Empowerment Of Procurement Teams:

RPA empowers procurement professionals by automating tedious tasks and freeing up their time for higher-value activities. This empowerment enables procurement teams to engage in strategic sourcing, supplier relationship management, and negotiation, leveraging their expertise to drive greater value for the organization.

6. Ensured Compliance:

RPA plays an important role in ensuring compliance with internal policies and external regulations governing procurement processes. It minimizes the risk of non-compliance and promotes a culture of adherence to industry standards by automating tasks related to regulatory compliance. This not only mitigates legal and financial risks but also enhances the overall integrity of the procurement function.

7. Focus On Strategic Tasks:

RPA empowers the procurement team to focus on more strategic tasks, leveraging their expertise to drive innovation, collaboration with suppliers, and risk mitigation. By automating mundane activities, RPA liberates valuable time and resources, enabling procurement professionals to contribute meaningfully to the organization’s strategic objectives.

8. Significant Returns On Investment:

Organizations that embrace RPA in procurement have reported substantial returns on investment (ROI). Studies indicate that top performers have earned nearly four times their initial RPA investments, while others have achieved significant cost savings and operational efficiencies. This underscores the compelling business case for adopting RPA in procurement and highlights its potential to deliver tangible financial benefits in the long run.

Top Use Cases And Application Of RPA In Procurement

Here are some of the use cases and applications of RPA in procurement:

1. Market Intelligence & Price Tracking:

Manual monitoring of competitor websites and vendor catalogs for pricing updates and product changes can be time-consuming and inefficient. However, with RPA, organizations can automate website scanning, extract pricing, and product details, and generate comprehensive reports. For instance, a furniture manufacturer can utilize RPA to monitor fluctuations in wood prices from various suppliers, enabling swift responses to market shifts and optimized purchasing strategies.

2. Input Identification:

In procurement, RPA plays a crucial role in streamlining the identification of inputs required for manufacturing or operations. By leveraging automation, RPA systems are able to extract essential data from Bills of Materials (BOMs) and centralize it for efficient decision-making. For example, in the automotive industry, an RPA system swiftly gathers data from BOMs, aiding decision-making and optimizing the supply chain process.

2. Supplier Performance Analysis:

Procurement isn’t just about price; it’s about building strong supplier relationships. RPA can analyze data from invoices, delivery reports, and performance reviews to identify top performers and potential issues with existing suppliers. A pharmaceutical company uses RPA to track on-time deliveries and product quality, enabling it to address concerns and maintain a reliable supply chain proactively.

3. Purchase Request & Purchase Order Submission:

The automation of purchase requests is a key area in which RPA brings significant benefits. By utilizing digital templates, RPA eliminates manual processes and expedites decision-making by swiftly processing requests for goods or services. For instance, in a technology company, an RPA system accelerates procurement by automating the submission and approval of purchase orders.

4. Risk Management & Compliance:

Staying ahead of potential disruptions and ensuring regulatory compliance are crucial aspects of successful procurement. RPA bots can scan news feeds and government websites for relevant alerts, triggering workflows to mitigate risks or ensure compliance actions are taken. For example, an electronics manufacturer leverages RPA to track potential factory closures due to external events, allowing them to source alternative components and minimize production delays.

5. Automated Re-ordering:

RPA enhances inventory management by automating the generation of purchase orders based on predefined criteria. Continuous monitoring of inventory levels ensures that essential products are always available, preventing disruptions in operations. In retail, for example, an RPA system manages inventory, ensuring seamless restocking of products and optimizing supply chain operations.

6. Dispute Resolution & Invoice Reconciliation:

Manual invoice processing can be a time-consuming and error-prone task. RPA can automate invoice matching with purchase orders, identify discrepancies, and initiate communication with vendors to resolve issues. A retail chain implements RPA to streamline invoice reconciliation, freeing up procurement staff to focus on complex disputes that require human judgment.

7. Inventory Management:

Integration of RPA with IoT enables real-time monitoring of inventory levels and automated reporting. RPA systems track inventory levels and provide valuable insights into stock optimization and demand forecasting. For example, in the pharmaceutical industry, an RPA system tracks inventory in real time, ensuring optimal stock levels and minimizing wastage.

8. Spend Analysis & Category Management:

Optimizing spending across different categories is a key objective for any procurement team. RPA can collect data from various sources, categorize purchases, and generate reports with insights on spending patterns. This allows for data-driven decision-making to identify cost-saving opportunities. For instance, a hospital utilizes RPA to analyze medical supply spending. By identifying high-cost items, they can negotiate better prices with vendors and optimize their budget allocation.

9. Three-Way Matching:

RPA automates the process of matching purchase requests, supplier invoices, and delivery receipts to ensure accuracy. By comparing data across multiple documents, RPA reduces errors and ensures compliance with procurement policies. In logistics, for instance, an RPA system streamlines the matching process, improving efficiency and reducing the risk of discrepancies.

10. Sustainability Reporting & Sourcing:

With growing digitization, ethical sourcing practices are increasingly important. RPA can automate the collection of data on a supplier’s environmental and social practices from their websites and reports. This allows for a more efficient assessment and comparison of potential vendors based on sustainability criteria. A clothing company can leverage RPA to analyze supplier data on water usage and labor practices, ensuring they source materials from environmentally conscious and ethical manufacturers.

11. Automated Payments:

RPA schedules and processes payments based on predefined criteria, ensuring timely transactions. By automating payment processes, RPA strengthens supplier relationships and enhances financial management. In finance, for example, an RPA system automates payment processing, reducing manual errors and improving efficiency.

12. Contract Renewal & Negotiation Management:

Keeping track of expiring contracts and initiating negotiations can be a tedious task. RPA can automate contract management by identifying expiration dates, sending reminders, and extracting key terms for negotiation. This allows procurement teams to manage contracts and secure the best possible terms proactively. For example, a software company utilizes RPA to manage software license renewals, enabling them to initiate negotiations early and potentially save on costs.

13. Supplier Onboarding:

RPA automates the onboarding process for new suppliers, extracting essential information and assessing suitability. By streamlining onboarding tasks, RPA reduces administrative burden and enables faster integration of new suppliers. In manufacturing, for instance, an RPA system automates supplier onboarding, ensuring compliance and reducing lead times.

14. Catalog Management & Parts Standardization:

Maintaining an accurate product catalog and identifying opportunities for parts standardization is crucial for efficient procurement. RPA can automate product data entry and updates based on supplier information. Additionally, it can analyze purchasing data to identify redundant parts and propose standardization. An automotive manufacturer can use RPA to manage their parts catalog, reducing errors and streamlining the procurement process. Standardized parts also lead to cost savings through bulk purchasing.

15. Price Negotiation:

RPA facilitates automated negotiation of prices based on predefined criteria and thresholds. By analyzing vendor quotes and comparing them against established benchmarks, RPA optimizes costs. In retail, an RPA system automates price negotiation, ensuring competitive pricing strategies and improving profitability.

16. User Provisioning & Access Control:

Managing user accounts and access permissions for internal and external procurement users can be a time-consuming task. RPA can automate user provisioning based on predefined roles and access levels. This ensures efficient user onboarding and strengthens security by granting access only to authorized personnel. For example, a construction company leverages RPA to manage access to its procurement portal for subcontractors, preventing unauthorized access to sensitive data.

17. Digitized Records:

RPA automates the creation of journal entries post-payment, enhancing efficiency and accuracy. By digitizing records, RPA improves auditability and compliance with accounting standards. For example, in a multinational corporation, an RPA system manages financial records, ensuring accuracy and transparency in financial reporting.

18. Post-Purchase Feedback & Performance Management:

Gathering feedback on purchased products or services and evaluating supplier performance is essential for continuous improvement. RPA can automate the generation and distribution of post-purchase surveys. It can also analyze survey responses and supplier performance data to identify areas for improvement and build stronger supplier relationships. This allows procurement teams to make informed decisions for future purchases.

Top 5 Brands Using RPA For Procurement

Here are some well-known brands in different sectors that are publicly known to be using RPA for procurement:

1. Retail:

Walmart uses robots to handle repetitive tasks like processing purchase orders and checking invoices. This frees up their staff to focus on more strategic work like planning future inventory and negotiating better deals with suppliers.

2. Manufacturing:

Ford leans on RPA to manage supplier information and automate parts ordering in their complex supply chain. This ensures they have the right parts at the right time to keep their production lines running smoothly.

3. Finance:

HSBC benefits from RPA by automating various procurement tasks. This includes processing invoices from suppliers and managing contracts, leading to a more efficient and error-free procurement process.

4. Healthcare:

Mayo Clinic utilizes RPA to automate managing purchase orders for medical equipment and supplies. This ensures timely deliveries and reduces administrative work, allowing staff to focus on patient care.

5. Energy:

Schneider Electric is a global leader in energy management and automation solutions. It is known to leverage RPA across various departments, including procurement. The specific applications might involve automating tasks related to supplier onboarding or contract management.

Challenges And Considerations For RPA Implementation In Procurement

When considering the implementation of Robotic Process Automation (RPA) in procurement, several challenges and key considerations must be taken into account to ensure successful deployment and maximize the benefits:

1. Challenges:

1.1. Process Identification & Standardization:

Procurement processes vary in complexity and may not always be well-defined or standardized. Identifying and standardizing processes suitable for RPA automation can be a time-consuming task.

1.2. Data Integration & Quality:

RPA relies heavily on accurate data inputs. Poor data quality or siloed data systems can lead to errors and inefficiencies in the automated processes, undermining the benefits of RPA.

1.3. Technical Expertise:

Implementing and maintaining RPA solutions require specific technical expertise, including programming skills and knowledge of automation tools. Procurement teams may lack the necessary expertise, necessitating additional training or external support.

1.4. Change Management:

Transitioning to RPA automation can disrupt existing workflows and require changes in employee mindsets. Effective change management strategies are essential to ensure smooth adoption and minimize resistance from staff members.

1.5. Security Concerns:

As RPA bots interact with sensitive procurement data, robust security measures are paramount to prevent data breaches, fraud, or unauthorized access. Ensuring compliance with data protection regulations is crucial.

2. Considerations:

2.1. Cost-Benefit Analysis:

Conduct a comprehensive cost-benefit analysis to evaluate the potential savings and efficiency gains from RPA automation against the initial investment and ongoing maintenance costs. Consider both short-term and long-term financial implications.

2.2. Scalability:

Choose an RPA solution that can scale to accommodate the evolving needs of your procurement operations as your business grows. Ensure flexibility and scalability to handle increased transaction volumes and complexity.

2.3. Integration With Existing Systems:

Ensure seamless integration of the chosen RPA solution with your existing procurement software and other enterprise systems. Compatibility and interoperability are essential for smooth implementation and operation.

2.4. Vendor Selection & Training:

Select a reputable RPA vendor with experience in the procurement domain and a proven track record of successful implementations. Provide comprehensive training to your procurement team to effectively utilize and manage RPA tools and workflows.

2.5. Return On Investment (ROI) Measurement:

Establish clear metrics and key performance indicators (KPIs) to track the ROI of your RPA implementation. Measure improvements in efficiency, cost savings, process accuracy, and employee productivity over time.

Conclusion

RPA’s arrival in procurement promises a future of efficiency, accuracy, and strategic decision-making. By automating repetitive tasks, RPA frees procurement teams for higher-value work, driving business growth. From streamlining operations to optimizing costs, RPA’s transformative power is felt across industries. However, challenges like process standardization and data quality require careful planning. Successful implementation also hinges on factors like scalability, integration, and vendor selection. By proactively addressing these considerations, businesses can unlock the full potential of RPA, paving the way for a competitive edge in the digital age.

How Can Idea Usher Help You?

Idea Usher, a leading app development company with extensive experience in AI projects, can transform your procurement function with RPA. We specialize in developing custom RPA solutions that automate repetitive tasks, freeing up your procurement team to focus on strategic initiatives.

Our team of AI experts will work with you to identify the most impactful areas for automation, like purchase orders and invoice reconciliation. We’ll then develop a custom RPA solution that seamlessly integrates with your existing systems, ensuring a smooth and efficient implementation.

Idea Usher goes beyond just development. We’ll guide you through the entire RPA project lifecycle, addressing challenges like process standardization and data quality. Contact us, and let’s unlock the full potential of RPA and achieve significant cost savings, improved accuracy, and a more streamlined procurement process.

FAQ

What is RPA in the supply chain?

RPA in the supply chain refers to the use of robotic process automation to automate repetitive tasks in the supply chain process, such as data entry, order processing, and inventory management, thereby improving efficiency and reducing errors.

What is automation in procurement?

Automation in procurement involves using technology to streamline and automate various procurement processes, including purchase requisitions, vendor management, contract management, and invoice processing, leading to increased efficiency, cost savings, and improved decision-making.

Is RPA part of SAP?

While RPA can be integrated with SAP systems for enhanced automation capabilities, it is not a built-in component of SAP. However, RPA tools can complement SAP systems to automate manual tasks and optimize processes.

What does RPA stand for in contracts?

In contracts, RPA stands for Robotic Process Automation. RPA in contract management involves using software robots to automate tasks such as contract creation, approval workflows, renewal reminders, and data extraction from contracts, improving accuracy, efficiency, and compliance.

Rebecca Lal