- Understanding the Role of RPA in Supply Chain

- Key Market Takeaways for RPA in Supply Chain

- Benefits of RPA in Supply Chain

- RPA Supercharges Supply Chain Processes: Use Cases

- How to Overcome the Roadblocks of RPA Implementation For Supply Chains?

- RPA Implementation for Your Supply Chain: A Deep Dive

- Must-Have Features in a RPA Supply Chain Platform

- Top 7 RPA Supply Chain Platforms in the USA

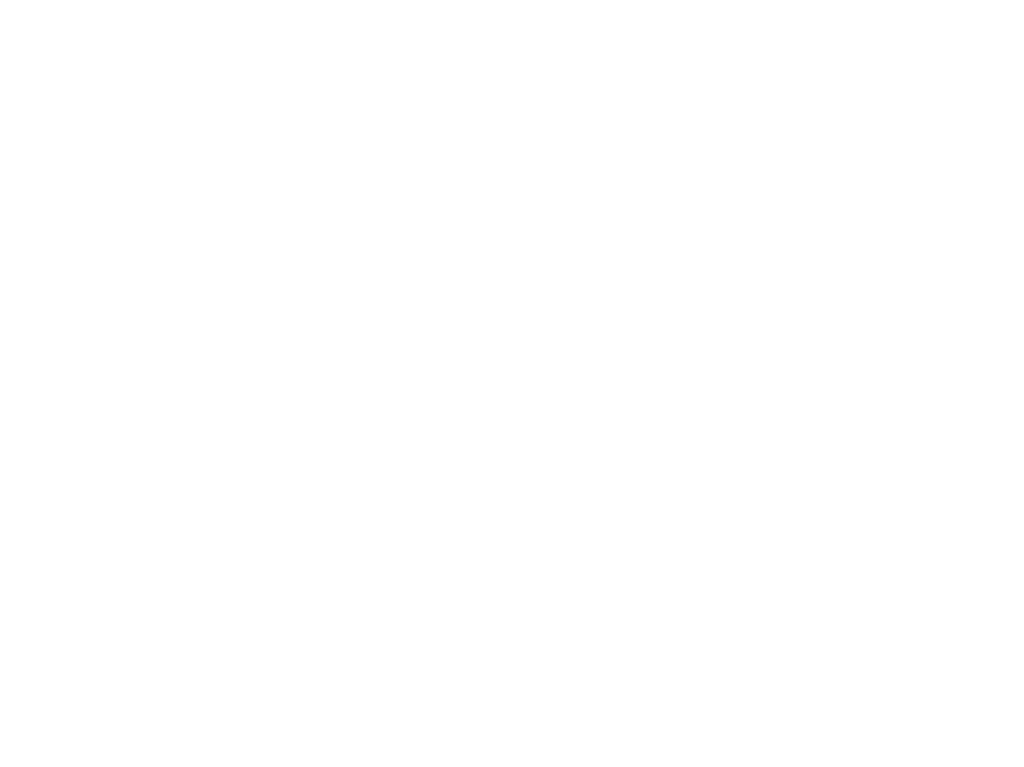

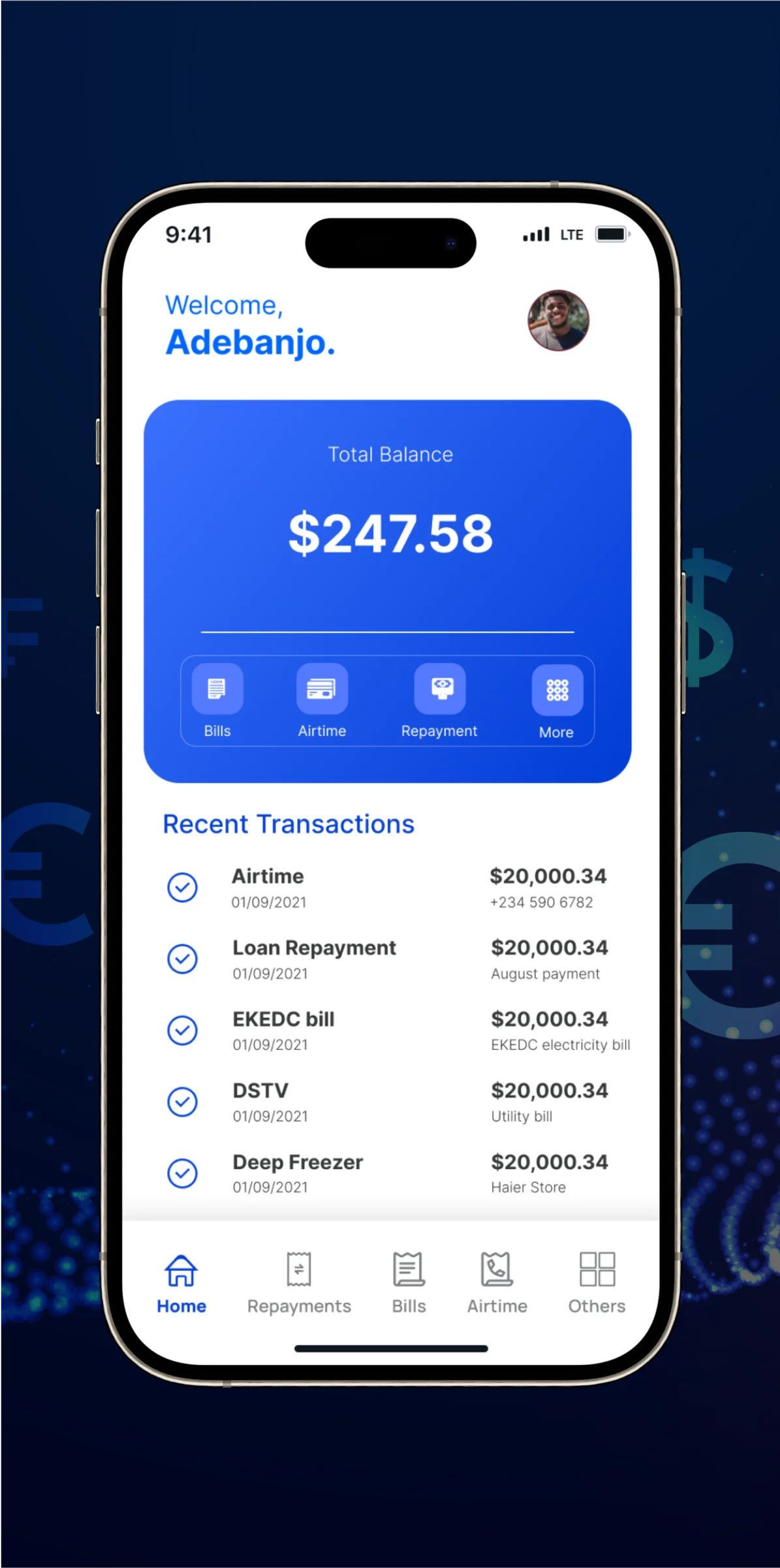

- Some of Our Recent Projects at Idea Usher

- Conclusion

- Looking to Implement RPA in Your Supply Chain?

- FAQs

Today’s diverse business landscape demands a supply chain that’s agile and efficient. But manual processes and data silos can create bottlenecks, hindering your ability to meet customer demands. Here’s where Robotic Process Automation (RPA) steps in as your game-changer. This innovative technology automates repetitive tasks across your supply chain, streamlining operations and boosting productivity. In this blog, we’ll explore how RPA can be your secret weapon, diving into real-world use cases and uncovering the benefits that can propel your supply chain toward peak performance.

- Understanding the Role of RPA in Supply Chain

- Key Market Takeaways for RPA in Supply Chain

- Benefits of RPA in Supply Chain

- RPA Supercharges Supply Chain Processes: Use Cases

- How to Overcome the Roadblocks of RPA Implementation For Supply Chains?

- RPA Implementation for Your Supply Chain: A Deep Dive

- Must-Have Features in a RPA Supply Chain Platform

- Top 7 RPA Supply Chain Platforms in the USA

- Some of Our Recent Projects at Idea Usher

- Conclusion

- Looking to Implement RPA in Your Supply Chain?

- FAQs

Understanding the Role of RPA in Supply Chain

Within the dynamic landscape of supply chain management, Robotic Process Automation (RPA) is rapidly gaining traction as a powerful tool for optimization.RPA leverages software bots to automate well-defined, high-volume tasks across disparate systems within the supply chain ecosystem. These bots mimic human actions by interacting with applications and databases, streamlining processes like data entry (order details, product information, shipment data), inventory management (stock level monitoring, purchase order generation, discrepancy reconciliation), order processing (information extraction, data validation, confirmation generation), and supplier communication (automated emails regarding orders, deliveries, invoices).

By automating these repetitive, rule-based tasks, RPA empowers human capital to focus on higher-order functions within the supply chain, such as strategic planning and data analysis. This not only enhances overall efficiency and accuracy but also unlocks a multitude of benefits. From faster processing times and reduced manual errors to improved supply chain visibility through real-time data and cost savings due to lowered labor requirements, RPA offers a compelling proposition for organizations seeking to optimize their supply chain operations.

Key Market Takeaways for RPA in Supply Chain

Source: SnsInsider

RPA automates repetitive tasks in supply chain management, freeing employees for strategic work. McKinsey estimates RPA can automate 70% of logistics tasks, leading to significant cost savings. Automating tasks also reduces errors, improves data accuracy, and speeds up processes. A Deloitte study found a 25% reduction in order processing time for companies using RPA. Real-time data from these automated processes provides better visibility into inventory, production, and deliveries, enabling better planning and responsiveness. One major food and beverage company used RPA to automate warehouse data collection for optimized inventory management.

Benefits of RPA in Supply Chain

Robotic Process Automation (RPA) is revolutionizing supply chain management by automating repetitive tasks. This translates into a multitude of benefits for businesses, enhancing efficiency, accuracy, and overall supply chain performance. Here’s a closer look at the key advantages of RPA:

1. Higher Quality Services:

RPA minimizes human error in data entry, order processing, and other critical tasks. This leads to fewer mistakes, improved data accuracy, and, ultimately, higher quality services delivered to customers. Faster turnaround times and consistent performance contribute to a positive customer experience.

RPA bots can be programmed with specific quality control measures, such as:

- Data validation checks: RPA bots can compare data points with predefined rules or reference databases to identify inconsistencies and flag potential errors.

- Automated error notifications: In case of data discrepancies, bots can automatically notify relevant personnel for corrective action, preventing errors from progressing through the workflow.

- Integration with Machine Learning (ML): Advanced RPA platforms can integrate with ML algorithms. These algorithms can continuously learn from historical data and identify patterns that might indicate potential issues. This enables proactive error detection and correction.

2. Greater Compliance:

Automating tasks with RPA ensures consistent adherence to regulations and compliance standards. This is especially valuable in industries with strict regulations, such as pharmaceuticals or food safety. RPA eliminates the chances of human error in following complex compliance protocols.

RPA bots can be programmed to follow specific compliance rules using:

- Decision trees: These are flowcharts that define the actions a bot should take based on specific criteria. For compliance purposes, decision trees can be programmed to ensure tasks are completed according to regulations.

- Integration with regulatory databases: RPA platforms can connect to regulatory databases to verify information and ensure adherence to the latest compliance requirements.

3. Increased Speed:

RPA bots work 24/7, significantly accelerating supply chain processes. Tasks like order processing, invoice generation, and inventory management can be completed much faster, leading to faster delivery times and improved overall supply chain agility.

RPA leverages pre-programmed workflows and digital interfaces to automate tasks with minimal human intervention. This eliminates processing delays associated with manual work and streamlines data exchange between different systems. Key technical aspects for speed include:

- Screen scraping: RPA bots can extract data from various applications by mimicking human interaction. This eliminates the need for manual data entry from different systems.

- API integration: RPA can connect to application programming interfaces (APIs) to exchange data seamlessly between different software programs used in the supply chain.

Retail giant Walmart deployed RPA to automate inventory data entry and stock level updates across its vast network of warehouses. This resulted in a 20% reduction in stockouts and improved overall inventory management efficiency.

4. Increased Ability to Scale:

RPA allows businesses to scale their automation as needed easily. New processes can be automated quickly, enabling companies to adapt to changing business demands and market fluctuations.

Modern RPA platforms offer scalability features like:

- Multi-bot deployment: Businesses can deploy multiple bots to handle high-volume tasks, distributing the workload and further accelerating processing times.

- Cloud-based infrastructure: Cloud-based RPA platforms offer greater flexibility and scalability. Businesses can easily add or remove bots based on their automation requirements without investing in additional hardware infrastructure.

Global logistics provider DHL implemented RPA to automate customs documentation for international shipments. This resulted in a 40% improvement in processing time and a significant decrease in errors associated with manual data entry.

5. Comprehensive Insights:

Automating tasks with RPA generates a wealth of data that can be used to gain better insights into supply chain performance. This data can be analyzed to find out bottlenecks, optimize processes, and make data-driven decisions.

RPA integrates seamlessly with existing data analytics tools. Data generated from automated tasks can be fed into dashboards and reporting tools using:

- Event logs: RPA platforms record detailed logs of all bot activities. This data can be analyzed to identify process bottlenecks, errors, and areas for improvement.

- Performance metrics: RPA platforms track key performance indicators (KPIs) associated with automated tasks. These metrics can be used to measure the efficiency and effectiveness of RPA implementations.

6. Reduced Costs:

By automating repetitive tasks, RPA significantly reduces labor costs associated with manual work. Additionally, fewer errors and improved efficiency lead to cost savings in areas like rework and inventory management.

A study by Accenture found that companies leveraging RPA in the supply chain can achieve a cost reduction of up to 20% through the automation of manual processes.

7. Improved Employee Experience:

RPA frees up employees from tedious, repetitive tasks, allowing them to focus on more important work that requires human judgment and creativity. This leads to increased employee satisfaction, improved morale, and higher productivity. Employees can leverage their skills for tasks like:

- Exception handling: RPA excels at handling routine tasks, but unexpected situations may arise. Employees can focus on resolving exceptions and addressing issues that require human intervention.

- Process improvement: Employees can analyze data generated by RPA to identify areas for process improvement. Their expertise is crucial for fine-tuning automated workflows and optimizing overall supply chain performance.

RPA Supercharges Supply Chain Processes: Use Cases

Here’s a deeper dive into some of the critical use cases of RPA in the supply chain,

1. Order Processing and Payments:

RPA bots act as digital assistants, seamlessly integrating with existing Order Management Systems (OMS) and Enterprise Resource Planning (ERP) software. They can extract order data in real time, validate pricing and availability against dynamic databases, and automatically generate invoices. Additionally, RPA can trigger secure payment processes through integrations with electronic payment gateways.

According to a 2023 report by Everest Group, companies leveraging RPA in order processing have witnessed a staggering 70% reduction in processing errors and a 35% improvement in order fulfillment speed.

2. Email Automation:

RPA eliminates manual email tasks by integrating with email servers like Microsoft Exchange or Google Workspace. Bots can extract data from incoming emails (e.g., order confirmations and shipment details) and trigger predefined actions such as sending automated responses or updating internal systems. Additionally, RPA can be programmed to generate and send bulk emails for tasks like order confirmations, shipment notifications, and status updates.

RPA streamlines communication, reduces manual workload for employees, and ensures timely responses to customer inquiries, leading to increased customer satisfaction.

3. Inventory Management Automation:

RPA bots can automate critical inventory management tasks, including real-time stock level updates, automatic purchase order generation based on predefined reorder points, and low-stock alerts. Integration with Warehouse Management Systems allows for real-time inventory visibility and data synchronization across the supply chain.

A recent Gartner forecast predicts that by 2025, 75% of large enterprises will leverage RPA for inventory management tasks, leading to improved stock accuracy and reduced stockouts.

4. Vendor Selection:

RPA streamlines vendor selection by automating data collection and analysis from various sources like vendor websites, industry databases, and internal purchase records. Using predefined criteria, bots can generate reports and comparisons to identify the best suppliers based on factors like pricing, quality, and delivery timelines.

RPA saves time and resources traditionally spent on manual vendor research, ensures a consistent evaluation process, and empowers businesses to identify the best suppliers for their needs.

5. Shipment Status Communication:

RPA integrates with logistics tracking systems (e.g., FedEx, UPS) and automates sending shipment status updates to customers via email or SMS notifications. This can be customized based on shipment milestones or customer preferences.

RPA enhances customer satisfaction by providing real-time shipment information, reduces the need for manual tracking inquiries, and frees up customer service resources for more complex issues.

6. Supply & Demand Planning:

RPA automates data gathering from diverse sources like sales records, customer purchase history, and market research data. This consolidated data can then be fed into advanced forecasting software to improve the accuracy of supply and demand planning.

RPA reduces the time spent on manual data collection, improves the accuracy of forecasting models, and helps businesses optimize inventory levels to meet fluctuating customer demand.

Leading sportswear brand Adidas implemented RPA to automate order processing across its global network. This resulted in a 50% improvement in processing time and a significant decrease in order fulfillment errors.

7. Returns and Refunds Processing:

RPA integrates with customer relationship management (CRM) systems and order management systems to automate returns processing. Bots can validate return requests, generate return merchandise authorization (RMA) numbers, and initiate refunds based on predefined rules. Additionally, RPA can automate communication with customers regarding return status and estimated timelines for refunds.

RPA streamlines return processing, reduces manual workload for customer service representatives, and improves overall customer experience by ensuring faster resolution times for return inquiries.

8. Customs Clearance and Documentation Management:

RPA can automate tasks associated with customs clearance and trade documentation. Bots can extract data from shipping invoices, packing lists, and other trade documents. This data can then be used to populate customs declarations and other regulatory forms electronically. Additionally, RPA can integrate with government databases to verify trade compliance and expedite the customs clearance process.

A 2023 study by McKinsey & Company found that using RPA for customs clearance can reduce processing times by up to 50%, leading to faster product delivery and improved cash flow for businesses.

How to Overcome the Roadblocks of RPA Implementation For Supply Chains?

Robotic Process Automation (RPA) promises significant benefits in supply chain management, but implementing it successfully comes with its own set of hurdles. Here’s a detailed guide on how to overcome them,

Challenge 1: Process Standardization

Problem: Complex, unstructured workflows with frequent variations make it difficult to automate tasks effectively. RPA bots struggle to adapt to inconsistencies, leading to errors and requiring constant maintenance.

Solution: Standardization is key. Businesses need to:

- Map and document existing processes in detail, identifying all steps and decision points.

- Identify opportunities for simplification by eliminating unnecessary steps or consolidating similar tasks.

- Develop clear guidelines for handling exceptions and unexpected situations.

Technical Insights: Process mining tools can be used to analyze historical data and identify areas for standardization.

Challenge 2: IT Support

Problem: Lack of adequate IT support can hinder successful RPA implementation. IT teams play a crucial role in:

- Infrastructure setup and maintenance for RPA platforms.

- Integration with existing IT systems used in the supply chain.

- Data security measures to ensure data integrity.

Solution: Early and active involvement of IT teams is essential throughout the RPA journey. Businesses need to:

- Establish clear communication channels between business process owners and IT teams.

- Invest in IT skills development related to RPA implementation and management.

A 2023 Gartner report highlights that 70% of RPA implementation failures can be attributed to inadequate IT support.

Challenge 3: Flexibility for a Changing World

Problem: Traditional RPA solutions lacked the ability to learn and adapt to changing processes. This inflexibility could lead to automation becoming outdated and requiring frequent reprogramming.

Solution: The integration of Artificial Intelligence (AI) and Machine Learning (ML) is transforming RPA. This allows bots to:

- Learn from historical data and figure out patterns to improve automation accuracy.

- Adapt to process variations within predefined parameters, making them more robust.

Technical Insights: Consider RPA platforms that offer built-in AI and ML capabilities or integrate seamlessly with these technologies.

Manufacturing giant Siemens implemented RPA with AI capabilities to automate invoice processing. The system learns from processed invoices, improving its ability to handle variations in data formats over time.

Challenge 4: Stakeholder Alignment

Problem: Gaining buy-in from all stakeholders, including senior management and employees, is crucial for successful RPA adoption. Misconceptions about job displacement can create resistance to change.

Solution: Effective communication and stakeholder engagement are essential:

- Clearly communicate the benefits of RPA for both the organization and employees.

- Highlight the focus on upskilling employees to take on more strategic roles.

- Involve stakeholders in the RPA selection and implementation process.

A study by Everest Group found that companies with strong stakeholder engagement achieve 20% faster RPA deployment and a 30% higher return on investment (ROI)..

Challenge 5: Employee Engagement

Problem: Employee apprehension about job security and lack of understanding of RPA can lead to resistance and hinder adoption.

Solution: Building a supportive and collaborative environment is key:

- Provide clear communication and training to employees on how RPA will impact their roles and responsibilities.

- Focus on reskilling and upskilling initiatives to equip employees with new skills necessary for a more automated work environment.

RPA Implementation for Your Supply Chain: A Deep Dive

Here’s how you can effectively implement RPA in your supply chain,

1. Assessment & Planning:

Identify Automation Opportunities: Look for high-volume tasks with well-defined steps in:

- Order Processing (data extraction via screen scraping, order validation, invoice & label generation)

- Inventory Management (stock level updates via API integration, PO generation based on reorder points, low-stock alerts)

- Shipment Tracking (customer notifications via email/SMS integration)

- Customs Clearance (data extraction with OCR for scanned docs, electronic customs declarations)

Prioritize ruthlessly: Focus on tasks with the biggest impact. Consider:

- Processing Time Reduction: How much time can RPA save compared to manual processes?

- Error Rate Reduction: Can RPA minimize errors that are prone to human oversight?

- Cost Savings per Transaction: Can automation significantly reduce operational expenses?

2. Process Standardization & Documentation:

- Flowchart Everything: Clearly define each step in chosen processes using flowcharts or process mapping tools, including decision points and exceptions.

- Streamline for Efficiency: Look for ways to simplify processes by eliminating unnecessary steps or consolidating similar tasks.

3. Selecting the Right RPA Tool:

Evaluate Vendors: Assess technical aspects like:

- Scalability: Can the platform adapt to your growing automation needs?

- Security Features: Does it offer robust security measures to protect sensitive data?

- User Interface & Development Tools: How easy is it to use and develop RPA bots for your team?

- Integration Capabilities: Can it seamlessly integrate with your existing IT systems (ERPs, WMS)?

POC: Test Drive the Future: Conduct a Proof of Concept (POC) to:

- Assess Functionality: Test how well the platform handles your specific supply chain processes.

- Identify Challenges: Uncover any potential integration issues or limitations before full deployment.

4. Development & Deployment:

Build & Test RPA Champions: Develop RPA bots that mimic human actions for chosen processes. Consider:

- Screen Scraping for Legacy Systems: Can the platform extract data from outdated systems that lack APIs?

- API Integration for Seamless Data Exchange: Leverage APIs to ensure smooth data flow between your existing systems and the RPA platform.

Deployment & Change Management: Deploy the bots and develop a change management plan that includes:

- Employee Training: Train relevant personnel to interact with the RPA platform and monitor bot performance.

- Communication Strategy: Clearly communicate the benefits of RPA to employees and address any concerns about job displacement.

6. Monitoring & Continuous Improvement:

Track Your Wins: Monitor key metrics like processing time, error rate, and cost savings to measure RPA’s impact.

Optimize relentlessly: Regularly reassess processes to identify new automation opportunities. Consider:

- Process Mining Tools: These tools are used to analyze historical data from automated tasks and identify bottlenecks or areas for further optimization.

RPA with Built-in AI & ML: Explore platforms with AI/ML capabilities for:

- Continuous Learning: Enable bots to continuously improve accuracy by analyzing historical data patterns.

- Exception Handling: Allow bots to adapt to process variations within pre-defined parameters for increased robustness.

Upskill Your Workforce: Invest in ongoing training to equip your employees with new skills necessary for a data-driven supply chain environment.

Must-Have Features in a RPA Supply Chain Platform

As supply chains become increasingly reliant on data, automation solutions need to evolve beyond rote tasks. To thrive in this environment, RPA platforms must leverage cutting-edge technology to unlock new levels of optimization. Here are some important features that can transform your RPA platform into a powerful engine for supply chain success.

1. AI-powered Task Mining and Process Discovery with Advanced NLP:

Implement Natural Language Processing (NLP) with techniques like Named Entity Recognition (NER) and dependency parsing. This allows for a better understanding of user actions within applications, identifying not just task sequences but also the specific data objects manipulated.

Integrate process mining tools that leverage algorithms like inductive process discovery and conformance checking. These advanced techniques can not only discover workflows but also ensure that automation accurately reflects real-world user behavior.

2. Cognitive Automation with Explainable AI (XAI) for Exception Handling:

Utilize Explainable AI (XAI) frameworks to build interpretable supervised learning models for exception handling. XAI allows you to understand the rationale behind the model’s decisions, ensuring trust and enabling continuous improvement. Train these models on labeled datasets containing not just the exception type but also the underlying root cause data.

Additionally, explore anomaly detection with techniques like Isolation Forest or Local Outlier Factor (LOF) for unsupervised learning within supply chain data. This allows for the identification of not just deviations from historical patterns but also pinpointing specific data points contributing to the anomaly.

3. Low-code/No-Code Development with Robotic Process Language (RPL):

Move beyond basic RPL to explore frameworks that support advanced control flow structures and function calls. This enables the creation of highly modular and reusable RPA components. Integrate the platform with robotic testing frameworks like Robotic Testing Framework (RTF) or Selma. This allows for automated testing of RPA bots themselves, ensuring their functionality and reliability before deployment within the supply chain.

4. Real-time Process Monitoring with Apache Kafka and Advanced Streaming Analytics:

Implement Apache Kafka, a distributed streaming platform, to capture and process bot activity and process data in real time. Leverage stream processing frameworks like Apache Flink or Apache Spark Streaming for near-instantaneous analysis of data streams.

Integrate advanced streaming analytics tools that utilize techniques like Complex Event Processing (CEP) to identify patterns and correlations within real-time process data. This allows for real-time exception detection and proactive intervention within the supply chain.

5. Cloud-based Scalability with Kubernetes and Serverless Functions:

Utilize Kubernetes, a container orchestration platform, for managing the deployment and scaling of RPA bots across cloud environments. Kubernetes ensures consistent resource allocation and facilitates automatic scaling based on workload demands.

Explore serverless functions for specific tasks within RPA workflows. This eliminates the need for infrastructure provisioning and management, further enhancing scalability and cost-efficiency.

6. Advanced Exception Handling with Self-healing Mechanisms

Implement self-healing mechanisms within RPA bots with built-in retry logic and rollback capabilities. This allows bots to automatically recover from transient errors and attempt tasks again before escalating exceptions.

Integrate context-aware chatbots powered by natural language generation (NLG) for human-in-the-loop collaboration. These chatbots can dynamically provide relevant information, suggest potential solutions, and even guide human workers through complex exception resolution procedures.

7. Integration with IoT Message Queues and Blockchain Hyperledger Fabric:

Utilize message queuing protocols like MQTT or AMQP for real-time data exchange between the RPA platform and IoT devices. This ensures efficient and reliable communication with various sensors tracking inventory, location, or equipment status within the supply chain.

Explore integration with blockchain technology using Hyperledger Fabric, a permissioned blockchain framework. This allows for transparent tracking of goods throughout the supply chain by leveraging tamper-proof smart contracts for automated execution of specific actions based on predefined conditions.

Top 7 RPA Supply Chain Platforms in the USA

Here are the top RPA supply chain platforms currently in the USA market,

1. Pegasystems: Powering Intelligent Automation Across the Supply Chain

- Features: Pegasystems offers a robust RPA platform that goes beyond basic automation. Their platform integrates seamlessly with process mining tools, enabling businesses to identify the most impactful automation opportunities within their supply chains. Additionally, Pegasystems leverages AI and machine learning for intelligent document processing and decision automation, streamlining complex tasks and improving decision-making accuracy.

- Subscription Model: Generates recurring revenue as businesses scale their RPA deployments.

- Strategic Alliances: Collaborates with tech leaders (Microsoft, AWS) and consulting firms for comprehensive solutions.

2. UiPath: Orchestrating Efficiency Across the Supply Chain

- Features: UiPath offers a robust suite of tools for building, deploying, and managing RPA bots. Process mining capabilities help identify automation opportunities, while AI and machine learning streamline workflows and optimize automation. Integrations with various enterprise applications facilitate data exchange across the supply chain ecosystem.

- Revenue Generation: UiPath boasts a strong financial performance with annual recurring revenue (ARR) exceeding $1 billion. Their subscription-based model provides recurring revenue streams from a growing customer base.

- Recent Partnerships: UiPath has partnered with industry leaders like Microsoft, Google Cloud, and Accenture to expand its reach and offer comprehensive solutions for various industries, including the supply chain.

3. Blue Prism: Security-Centric Automation for Enterprise-Grade Supply Chains

- Features: Blue Prism specializes in secure and scalable RPA solutions. Pre-built connectors for popular supply chain applications accelerate deployment and reduce development time. Their focus on security is ideal for businesses handling sensitive data within their supply chain processes.

- Revenue Generation: Blue Prism is a firm that is listed on the stock exchange and has a market capitalization of $1 billion. Their revenue streams come from software licenses, maintenance fees, and training services.

- Recent Partnerships: Blue Prism has partnered with major technology companies like IBM and Microsoft to offer integrated RPA solutions. Additionally, they collaborate with consulting firms like EY and Deloitte to deliver RPA implementations for clients.

4. Automation Anywhere: Democratizing RPA for Businesses of All Sizes

- Features: Automation Anywhere offers a user-friendly, cloud-based platform that caters to businesses of all sizes. Their Discovery Bot tool helps identify automation opportunities within existing processes, empowering businesses to get started with RPA quickly. Cognitive automation features like natural language processing (NLP) enhance the platform’s capabilities for handling complex tasks.

- Revenue Generation: Automation Anywhere is a private company with a valuation exceeding $6.8 billion. Their revenue streams come from software subscriptions, implementation services, and training programs.

- Recent Partnerships: Automation Anywhere has partnered with leading technology companies like Amazon Web Services (AWS) and Google Cloud to offer cloud-based RPA solutions. Additionally, they collaborate with system integrators and consulting firms to expand their reach and provide comprehensive RPA implementations.

5. Microsoft Power Automate: Streamlining Supply Chains with Drag-and-Drop Ease

- Features: Microsoft Power Automate seamlessly integrates with the Microsoft Power Platform suite, offering a familiar environment for existing Microsoft users. Pre-built connectors streamline data exchange with popular supply chain applications like Dynamics 365. The intuitive drag-and-drop interface empowers users with minimal coding experience to build basic automation for tasks like order processing, inventory management, and shipment tracking.

- Revenue Generation: Microsoft leverages a subscription-based model for its Power Platform suite, including Power Automate. This model generates recurring revenue streams as businesses scale their RPA deployments.

- Recent Partnerships: Microsoft fosters a robust partner ecosystem, collaborating with system integrators and consulting firms to deliver comprehensive RPA solutions for supply chain automation.

6. NICE RPA: Prioritizing Security and Scalability for Enterprise-Grade Supply Chains

- Features: NICE RPA boasts robust security features ideal for organizations handling sensitive data within their supply chains. The platform offers high scalability to accommodate growing automation needs. NICE RPA integrates seamlessly with various enterprise applications commonly used in supply chain management and leverages AI and machine learning for enhanced automation capabilities.

- Revenue Generation: NICE RPA offers a combination of licensing models, including perpetual licenses and subscription plans. This caters to businesses with diverse budget constraints and deployment preferences. Revenue streams also come from implementation services and training programs.

- Recent Partnerships: NICE partners with technology providers like UiPath and Blue Prism to offer a broader range of RPA solutions.

7. IBM Robotic Process Automation: Leveraging the Power of IBM for Streamlined Supply Chains

- Features: IBM Robotic Process Automation integrates seamlessly with IBM’s broader automation portfolio, including IBM Cloud Paks and IBM Maximo Asset Management software. This tight integration offers a unified automation experience for organizations already invested in the IBM ecosystem. The platform automates routine tasks within supply chain processes, improving efficiency and data accuracy.

- Revenue Generation: IBM leverages a subscription-based model for its software offerings, including IBM Robotic Process Automation. This model generates recurring revenue streams as businesses scale their automation deployments within the supply chain.

- Recent Partnerships: IBM fosters a robust partner ecosystem, collaborating with system integrators and consulting firms to deliver comprehensive RPA solutions tailored to specific supply chain needs.

Some of Our Recent Projects at Idea Usher

At Idea Usher, we combine user-centric design with deep development expertise to craft innovative mobile and web applications. Here’s a glimpse of what we’ve achieved:

1. TicketBox

At Idea Usher, we take pride in crafting user-centric applications. Take Ticketbox, for example, a booking app designed with your customers’ convenience at its core. Its intuitive interface and seamless functionalities make booking a breeze, while features like ticket viewing and booking history tracking ensure effortless management. Secure payment gateways guarantee peace of mind, and real-time updates keep users informed throughout the process.

2. Shows Manager

We understand the challenges of managing large events. That’s why we have developed Shows Manager, a powerful event management platform designed to streamline ticket scanning and organization for our clients. This robust and intuitive platform tackles common group ticket scanning issues with advanced group and laser scanning functionalities, enhancing efficiency and eliminating frustration. Built with user-friendliness in mind, we’ve utilized Figma for a clear and intuitive design and Flutter for a smooth front-end experience. The result? A seamless event ticketing process for both organizers and attendees. Let Idea Usher help you take the stress out of event management.

3. Odyssey Travel App

Idea Usher’s expertise extends to the luxury travel sector. Tasked with taking Travel Hub 365’s exclusive offerings online, we crafted the Odyssey Travel App. Leveraging agile development methodologies, our team built a robust and scalable solution using PHP, Laravel for the backend, Flutter for app development, and AWS for hosting. This collaborative effort, with Stephen’s direct involvement, ensured the app perfectly captured the essence of luxury travel. Features like real-time inventory and a user-friendly UI/UX prioritize a seamless and sophisticated user experience. Let Idea Usher craft a travel app that elevates your brand.

Conclusion

RPA is revolutionizing the supply chain industry by automating repetitive tasks, boosting efficiency, and minimizing errors. From streamlining order processing and inventory management to optimizing logistics and data analysis, RPA unlocks significant cost savings and empowers businesses to focus on strategic initiatives. As RPA keeps evolving and integrating with AI and machine learning, the future of supply chains promises to be one of enhanced agility, resilience, and intelligent decision-making. By embracing RPA now, businesses can gain a competitive edge and navigate the ever-changing demands of the global marketplace.

Looking to Implement RPA in Your Supply Chain?

Leverage the power of RPA to optimize your supply chain! Idea Usher boasts a team of RPA specialists with over 1000+ hours of RPA development experience. We’ll analyze your workflow, pinpoint automation opportunities, and implement a custom solution that integrates seamlessly with your existing systems. Eliminate errors, streamline operations, and unlock a faster, more agile supply chain. Contact Idea Usher today and see the RPA revolution in action!

FAQs

Q1: How is automation transforming the supply chain?

A1: Automation, encompassing technologies like Robotic Process Automation (RPA) and artificial intelligence (AI), is transforming supply chains by automating mundane tasks like inventory management and data entry. This frees up human workers to focus on higher-value activities like strategic planning and customer service. Additionally, automation reduces errors and streamlines workflows, leading to faster turnaround times and improved efficiency.

Q2: How is robotics changing the supply chain?

A2: Robotics is revolutionizing supply chains by taking over physically demanding and hazardous tasks. Industrial robots perform tasks like welding, assembling components, and packaging finished goods with increased precision and speed. This not only improves worker safety but also boosts productivity and consistency in manufacturing processes.

Q3: What are robotics and automation in supply chain management?

A3: Combining robotics with automation creates a powerful force. RPA software can control and manage robots, enabling them to perform more complex tasks and adapt to changing production demands. This intelligent automation empowers businesses to optimize production lines, minimize downtime, and achieve greater flexibility in their supply chains.

Q4: What is the impact of RPA on the manufacturing industry?

A4: RPA, specifically, is having a significant impact on the manufacturing industry. By automating repetitive tasks in areas like production planning, quality control, and logistics management, RPA reduces manual errors and streamlines data exchange between different systems. This leads to improved production visibility, faster response times to issues, and ultimately, increased profitability for manufacturers.