In today’s fast-paced global economy, the efficiency and transparency of supply chain management are crucial for businesses to thrive. The advent of the Internet of Things (IoT) has revolutionized the way supply chains operate, offering a plethora of benefits that streamline processes, enhance visibility, and optimize decision-making. From real-time tracking to predictive maintenance, IoT technologies have reshaped the landscape of supply chain management. In this blog, we’ll delve into the top 10 benefits that IoT brings to supply chain management, illustrating how these advancements are transforming the industry and paving the way for unprecedented levels of efficiency and effectiveness.

What is IoT in the Supply Chain?

The implementation of the Internet of Things (IoT) in supply chain management involves utilizing interconnected devices and sensors to gather and transmit real-time data. This technology facilitates improved decision-making and the optimization of operations. Traditionally, supply chain management relied heavily on manual processes, resulting in inefficiencies and delays.

Here are some ways in which IoT is utilized in supply chains:

- Tracking and Monitoring: IoT devices are extensively employed to track and monitor processes within the supply chain. They provide unparalleled real-time visibility throughout the entire supply chain. Through the integration of sensors, devices, and data analytics, companies can monitor products, materials, and shipments at every stage of the supply chain journey.

- Quality Management: IoT devices serve as effective tools for tracking and authenticating products and shipments using GPS and other technologies. Additionally, they can monitor the storage conditions of products, enhancing quality management throughout the supply chain.

- Efficiency and Performance: Companies leverage IoT in supply chain management to enhance their efficiency and performance. IoT, in conjunction with other technologies like blockchain and analytics, facilitates the improvement of customer fulfillment, attainment of profitability targets, and the creation of more resilient and sustainable supply chains.

Key Market Takeaways of IoT in Supply Chain

Source: MarketsandMarkets

The rapid growth of the e-commerce industry is a major driving force behind the expansion of IoT in supply chain management. Businesses are under pressure to optimize their supply chain operations to meet rising consumer expectations for fast and seamless delivery, fueling demand for IoT-enabled solutions that offer real-time visibility and efficiency.

Key players like Cisco, Robert Bosch GmbH, IBM, Microsoft, Qualcomm Inc, Intel, and Honeywell are adopting various growth strategies to strengthen their market presence. These include new product launches, upgrades, partnerships, expansions, and mergers and acquisitions, showcasing the industry’s commitment to innovation and meeting market demands.

Recently, SAP’s initiative to create the world’s largest business network by integrating SAP Business Network, Ariba Network, SAP Logistics Business Network, and SAP Asset Intelligence Network is a significant development. This move aims to help companies modernize and digitize their business processes, highlighting the pivotal role of IoT in driving digital transformation.

Also read, “How To Hire IoT Developers? A Complete Guide“

10 Benefits of IoT in Supply Chain

Here are 10 essential benefits of IoT in the supply chain,

1. Increased Visibility

IoT technology bridges the digital-physical gap in supply chain management by equipping physical assets with sensors. This enables firms to track, locate, and monitor their status in real time.

For example, vehicles with sensors can track location and speed, providing maintenance alerts and reducing transit delays. Similarly, connected sensors ensure temperature stability for perishable goods, minimizing wastage. Additionally, smart IoT devices support dynamic inventory management, proactively alerting for shelf replenishment and predictive maintenance.

2. Better Collaboration

The integration of IoT in supply chain operations facilitates real-time data collection, transmission, and analysis via IoT sensors. These capabilities simplify oversight and organization of supply chains, including the transportation of goods. IoT data integrated into the ERP system can provide the most accurate real-time data to key decision-makers daily. Integrating IoT and supply chain processes offers greater speed, scale, and accuracy of data exchange. The better the collaboration among the multiple stakeholders of a supply chain, the stronger the supply chain becomes.

3. Maximizing Assets

Studies have shown that more effective routing can reduce driver hours by almost 25%. With the improved connectivity IoT brings, supply chain managers and logistics teams can optimize their fleets, provide smarter route planning, and identify assets that are delayed. IoT devices such as sensors, RFID tags, and GPS trackers provide real-time data on the location and condition of products throughout the supply chain. This data helps businesses monitor and manage their assets more effectively, improving overall supply chain visibility.

4. Better Customer Service

IoT enables a more connected supply chain, significantly improving customer service. Managers can access real-time information via mobile apps, making delivery-time forecasting precise. This real-time visibility allows for quick identification of delivery issues and better management of customer expectations.

Furthermore, IoT devices provide real-time data, enhancing the visibility and accuracy of inventory management. This application of IoT in the supply chain has revolutionized warehouse management by automating data collection and reducing manual labor.

5. Real-time Tracking of Sensitive Goods

IoT devices such as GPS monitors can track everything from a shipment’s location to its current temperature. Real-time tracking is particularly useful for high-value items and temperature-sensitive goods.

For example, IoT devices can flag shipments that have left a safe temperature zone, preventing customers from receiving spoiled goods. Internet-connected devices, including image, temperature, humidity sensors, and GPS trackers, enable the collection of real-time data about the goods being stored and transported, inventory level and shipment status, environmental conditions in warehouses and vehicles, etc.

6. Increased Productivity

IoT devices can automate many manual processes involved in supply chain management, such as tracking inventory levels and scheduling maintenance. This leads to increased productivity. IoT devices can help companies optimize their supply chain by reducing waste and allocating resources more efficiently. For example, IoT can optimize inventory levels, automate replenishment, and improve visibility throughout the chain.

7. Lower Costs

IoT can help businesses reduce costs by using sensors to locate the whereabouts of products or staff in large depots. Real-time traceability through IoT devices shared via blockchain provides visibility into the status of products and shipments, verified by all stakeholders across the value chain. With this visibility, companies can reduce the stock they hold as a buffer, promote more efficient inventory management, and lower holding costs.

8. Better Inventory Accuracy

IoT in supply chain management transforms how we control inventories, making supply chains more efficient. By integrating IoT devices like RFID tags and sensors, real-time data is collected, enhancing the visibility and accuracy of inventory management. IoT devices provide users with enough data for optimized inventory management, necessary for supply chain visibility. Additionally, IoT sensors can help prevent false inventory claims.

9. Streamlined Operations

The integration of IoT in supply chain operations facilitates real-time data collection, transmission, and analysis via IoT sensors. These capabilities simplify oversight and organization of supply chains, including the transportation of goods.

IoT solutions offer professionals the ability to swiftly assess the condition and quantity of inventory and react to order status changes. IoT technology builds the digital foundation that allows logistics companies to enhance visibility across the supply chain, track shipments in real time, optimize asset utilization, prevent losses, and delight customers.

10. Ideal Logistics

IoT helps businesses track good movement and conditions in real time. IoT-enabled smart contracts and blockchain can automate payment settlements. Either way, IoT reduces supply chain costs and improves supply chain efficiency in a nutshell. IoT devices can track and monitor the location, temperature, humidity, pressure, and other environmental factors of goods, enabling supply chain managers to optimize their operations, reduce costs, and improve efficiency.

Also read, “Top 10 IoT App Development Trends for Startups In 2024“

Benefits of IoT Supply Chain Across Different Industries

Let’s go over some of the benefits of IoT in the supply chain across different industries

1. Automotive Industry

- Track the Location and Condition of Vehicle Parts: IoT devices like GPS trackers and sensors provide real-time data on the location and condition of vehicle parts, enhancing overall supply chain visibility.

- Ensure Timely Delivery: IoT optimizes production by offering real-time data on equipment performance and product quality, identifying bottlenecks, and ensuring timely deliveries.

- Enable Predictive Maintenance: IoT collects vehicle performance data and uses machine learning to predict maintenance needs, reducing breakdowns and downtime.

- Reduce Downtime and Optimize Fleet Management: IoT predicts maintenance needs, schedules repairs proactively, and offers real-time data on vehicle location and status, optimizing fleet management and reducing downtime.

- Monitor Quality and Condition: IoT monitors the quality and condition of automotive components during manufacturing and transportation, ensuring products meet quality standards and arrive undamaged.

2. Pharmaceutical Industry

- Monitor Humidity and Temperature: IoT devices monitor humidity and temperature during transportation and storage, ensuring products are stored under appropriate conditions to maintain efficacy.

- Track Inventory Levels in Real-Time: IoT provides real-time data on inventory levels, ensuring accurate stock counts and avoiding stockouts or overstocking.

- Monitor Condition of Manufacturing Equipment: IoT monitors manufacturing equipment condition, identifying potential issues to prevent downtime and maintain product quality.

- Prevent Counterfeiting with Tamper-Evident Features: IoT in packaging provides tamper-evident features, preventing counterfeiting and ensuring patient safety.

- Track Usage of Pharmaceutical Equipment: IoT tracks usage of equipment in different locations, ensuring proper use and regular maintenance.

3. Construction Industry

- Track Location and Usage: IoT tracks materials and equipment usage, managing assets effectively and reducing waste.

- Enhance Safety and Security: IoT monitors sites for hazards, alerting authorities in emergencies to improve worker safety.

- Improve Inventory Management: IoT provides real-time data on inventory levels, enhancing stock management and reducing theft or loss.

- Enable Preventive Maintenance: IoT monitors equipment condition, predicting maintenance needs to prevent breakdowns and downtime.

- Monitor Energy Consumption: IoT monitors energy usage, helping businesses reduce costs and environmental impact.

4. Electronics Industry

- Combat Counterfeiting with Unique Identifiers: IoT provides unique identifiers and authentication protocols, combating counterfeiting in electronics.

- Insights for Demand Forecasting: IoT collects data on product usage and customer behavior, providing insights for demand forecasting.

- Optimize Energy Consumption: IoT monitors and controls energy usage, optimizing consumption in manufacturing facilities.

- Track Inventory Levels: IoT provides real-time data on inventory, improving stock management and avoiding stockouts or overstocking.

5. Oil and Gas Industry

- Monitor Remote Assets: IoT monitors remote assets like pipelines and rigs, improving asset management and reducing accidents or leaks.

- Detect Safety Hazards: IoT detects hazards like leaks or fires, enhancing worker safety and protecting the environment.

- Track Inventory in Real-Time: IoT provides real-time data on inventory levels, improving stock management and avoiding shortages.

- Track Movement of Goods and Equipment: IoT tracks the movement of goods, vehicles, and equipment, improving logistics and reducing waste.

- Enable End-to-End Visibility: IoT provides end-to-end visibility across the supply chain, improving operations and customer service.

6. Retail Industry

- Enhance Customer Experience: IoT devices in retail stores can track customer movement and behavior, enabling personalized experiences and targeted promotions.

- Optimize Inventory Management: IoT sensors can monitor inventory levels in real time, preventing stockouts, reducing overstocking, and improving overall inventory accuracy.

- Improve Supply Chain Efficiency: IoT-enabled supply chain management can provide real-time tracking of shipments, optimize route planning, and reduce transportation costs.

- Enable Smart Shelves: IoT-enabled smart shelves can automatically detect when products need restocking, improving shelf availability and reducing out-of-stock situations.

- Enhance Store Security: IoT devices can monitor store premises for suspicious activities, enabling proactive security measures and reducing the risk of theft or vandalism.

Also read, “Impact of IoT on Retail Industry“

7. Healthcare Industry

- Remote Patient Monitoring: IoT devices can monitor patient health metrics remotely, allowing healthcare providers to intervene early and prevent medical emergencies.

- Asset Tracking: IoT enables tracking of medical equipment and supplies, reducing loss and ensuring availability when needed.

- Improved Medication Management: IoT devices can monitor medication adherence and track medication usage, reducing errors and improving patient outcomes.

- Optimized Facility Management: IoT sensors can monitor environmental conditions in healthcare facilities, ensuring optimal conditions for patient care and equipment operation.

- Enhanced Telemedicine: IoT facilitates telemedicine by enabling remote consultations, monitoring, and diagnostics, improving access to healthcare services for patients in remote areas or with limited mobility.

How to Deploy IoT in Supply Chain?

Here’s how you can deploy IoT into supply chain management,

1. Identify the Needs

The first step in implementing IoT in your supply chain is to identify your specific needs. This could involve real-time tracking of goods, predictive maintenance of machinery, or even monitoring environmental conditions. The goal is to pinpoint areas where IoT can bring about efficiency and improvements.

2. Choose the Right IoT Devices

Depending on your needs, you’ll need to select appropriate IoT devices. These could range from sensors for tracking temperature or humidity, GPS trackers for location tracking, or other types of IoT devices. The choice of devices will depend on the specific requirements of your supply chain operations.

3. Integrate with Existing Systems

The chosen IoT devices need to be integrated with your existing supply chain management systems. This integration allows for the collection and analysis of data from IoT devices in real-time, providing valuable insights for decision-making.

4. Implement Security Measures

Given that IoT devices are connected to the internet, they are vulnerable to cyber-attacks. Therefore, it’s crucial to implement robust security measures to protect your data. This includes installing security software, regularly updating the software and firmware on the device, encrypting data, and implementing security measures such as surge protection and firewalls.

5. Monitor and Optimize

Once the IoT devices are deployed, continuous monitoring of their performance is necessary. The data provided by these devices can be used to optimize supply chain operations, improve efficiency, and reduce costs.

6. Invest in Device Design, Prototyping, and Pre-Deployment Testing

Before deploying IoT devices, it’s important to invest time and resources in device design, prototyping, and pre-deployment testing. This helps ensure that the devices meet your specific needs and can operate effectively in your supply chain environment.

7. Choose the Right Connectivity Partner

The success of your IoT deployment can depend on the quality of your connectivity. It’s important to choose a connectivity partner who can provide reliable, secure, and scalable connectivity solutions.

8. Enable Scalable Data Management & Analytics

IoT devices generate a large amount of data, which needs to be managed and analyzed effectively. Systems should be in place for scalable data management and analytics, allowing for the extraction of valuable insights to optimize supply chain processes.

9. Design-in Security as Part of a Holistic Strategy

Security is a critical aspect of any IoT deployment. You should design security into your IoT strategy from the start, ensuring that all devices, data, and communications are protected.

10. Plan for Flexible Device Management

As your IoT deployment grows, you will need to manage an increasing number of devices. Planning for flexible device management, which can adapt to your changing needs, is essential.

An Interesting Case Study of an IoT Supply Chain App: SenseAware

Launched by FedEx in November 2009, SenseAware was initially tailored to cater to the specific requirements of industries such as life sciences, biotechnology, pharmaceuticals, and healthcare. However, its scope has since broadened to encompass clients across various sectors, including aerospace, the arts, and financial institutions.

SenseAware stands as a pioneering information service, blending a GPS sensor device with a web-based collaboration platform. It offers an open, highly adaptable, and user-friendly sensor information-sharing platform, furnishing real-time insights into package status, including location, temperature, pressure, and shock.

Features:

- Real-time Data: SenseAware furnishes live data for ongoing shipments.

- Journey Control: Users retain complete authority over journey programming and monitoring.

- Security & Compliance: SenseAware offers enhanced assurance regarding the condition of sensitive cargo.

- Quality & Integrity: It upholds the quality and integrity of products throughout transit.

- Operational Visibility: Precise route monitoring ensures operational transparency.

- Temperature Tracking: Capable of monitoring temperatures ranging from -200°C to 60°C (-328°F to 140°F).

- Shock Detection: Enables monitoring of fragile shipments or inventory for potential shocks.

- Route Alerts: Alerts are triggered upon shipment entry or exit from designated routes.

- Location Alerts: Users receive alerts when shipments cross specified areas.

- Time-based Location Alerts: Alerts are triggered based on both location and specified times.

- Humidity Monitoring: Humidity levels can be monitored and verified.

SenseAware latest introduced SenseAware ID, a new sensor technology by FedEx. This compact device offers enhanced package visibility, especially for critical shipments like potential COVID-19 vaccine deliveries. Using Bluetooth Low Energy, it transmits precise location data every two seconds within the FedEx Express network, significantly improving tracking frequency compared to traditional methods.

Initially deployed for First Overnight shipments within the U.S., SenseAware ID supports FedEx’s transportation of pharmaceuticals and medical supplies for healthcare clients nationwide.

FedEx plans to prioritize SenseAware ID for First Overnight packages, targeting healthcare, aerospace, and retail sectors. Access to its advanced data capabilities will roll out starting in November, with broader availability planned for the first half of 2021. Expansion to include more premium Express services is also on the agenda.

Conclusion

the adoption of IoT in supply chain management represents a paradigm shift towards smarter, more agile, and resilient operations. As businesses navigate through the complexities of the global marketplace, leveraging IoT technologies can be a game-changer, unlocking new levels of efficiency, transparency, and competitiveness. Embracing this transformative potential promises to revolutionize supply chain processes, driving value creation and fostering innovation in the increasingly interconnected world of commerce.

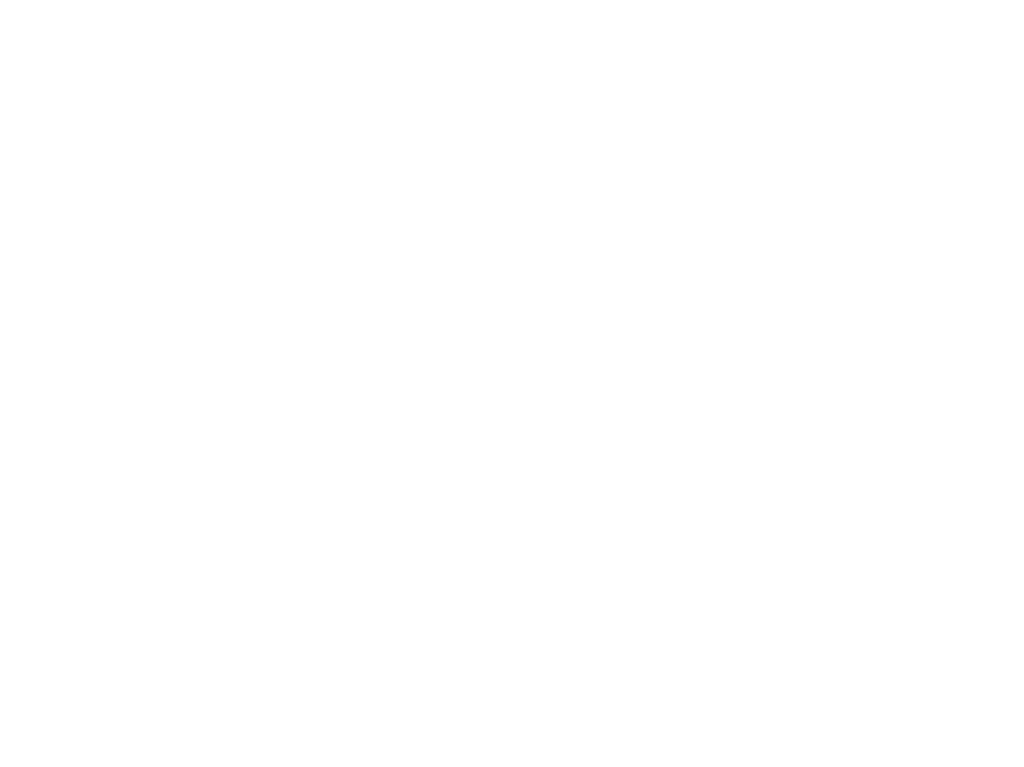

Looking to implement IoT in the Supply Chain for Your Business?

Interested in harnessing the power of IoT to revolutionize your supply chain operations? Look no further than IdeaUsher! Our team specializes in developing customized solutions, ranging from mobile apps to web applications, tailored to meet your specific needs. With our expertise in IoT integration and supply chain management, we can help you streamline processes, optimize resources, and stay ahead of the curve in today’s dynamic business landscape. Get in touch with us today to embark on your journey towards a smarter, more efficient supply chain ecosystem.

FAQs

Q1: What is the benefit of IoT in supply chain management?

A1: The primary benefit of IoT in supply chain management is enhanced visibility and traceability. By leveraging IoT devices such as sensors and RFID tags, businesses can gather real-time data on the location, condition, and status of goods throughout the entire supply chain. This visibility enables stakeholders to track inventory levels, monitor the movement of goods, and identify potential bottlenecks or disruptions, leading to improved decision-making, increased efficiency, and reduced operational costs.

Q2: What are at least 3 IoT benefits to organizations?

A3: IoT drives operational efficiency by automating processes and optimizing resources through data analysis. Predictive maintenance ensures machinery health by monitoring real-time performance, reducing downtime, and preventing costly failures. Supply chain optimization is achieved through end-to-end visibility and collaboration, integrating IoT devices into inventory, logistics, and procurement for improved responsiveness and customer satisfaction. These benefits collectively enhance organizational performance, streamline workflows, and foster competitiveness in the market.

Q3: How IoT can improve the logistics process?

A3: IoT enhances logistics with real-time tracking via sensors and GPS, enabling constant monitoring of shipment location and condition. Optimized routing, driven by IoT data analytics, adjusts routes based on traffic, weather, and delivery priorities, cutting transportation costs and improving punctuality. Additionally, IoT-enabled inventory management offers up-to-date inventory data, aiding in stock level optimization, reducing stockouts, and enhancing turnover ratios. These IoT applications revolutionize logistics by increasing efficiency, reducing costs, and improving customer satisfaction.

Q4: What is the relationship between IoT and supply chain management?

A4: The relationship between IoT and supply chain management is symbiotic. IoT technology provides the infrastructure and tools necessary to capture and analyze vast amounts of data across the entire supply chain ecosystem. This data-driven approach enables organizations to gain insights into various aspects of supply chain operations, including inventory management, logistics, production, and demand forecasting. By leveraging IoT solutions, businesses can enhance visibility, improve decision-making, and optimize processes, ultimately driving efficiency, agility, and competitiveness in today’s dynamic marketplace.