- What is IoT in Construction?

- Key Market Takeaways for IoT in Construction

- Important Use Cases of IoT in Construction

- Interesting Benefits of Using IoT in Construction

- Mitigating Challenges of Implementing IoT Solutions in Construction

- What is the Future of IoT in the Construction Sector?

- Top 7 IoT Platforms Used For Construction Projects

- Some of Our Projects at Idea Usher

- Conclusion

- Looking to Implement IoT in Construction?

- FAQs

The construction industry is currently undergoing a significant transformation driven by data and IoT. Using a range of powerful IoT tools, construction projects can now be managed more efficiently, with streamlined operations, reduced risks, and optimized resource utilization.

In this blog, we will discuss how IoT can supercharge your construction business. We will dive deeper into the core principles of this transformative technology, along with its benefits. Most importantly, we will showcase some real-world use cases that demonstrate how IoT can fundamentally change the way you approach your construction projects.

- What is IoT in Construction?

- Key Market Takeaways for IoT in Construction

- Important Use Cases of IoT in Construction

- Interesting Benefits of Using IoT in Construction

- Mitigating Challenges of Implementing IoT Solutions in Construction

- What is the Future of IoT in the Construction Sector?

- Top 7 IoT Platforms Used For Construction Projects

- Some of Our Projects at Idea Usher

- Conclusion

- Looking to Implement IoT in Construction?

- FAQs

What is IoT in Construction?

The IoT technology in construction refers to using a network of internet-connected devices to collect data and improve various aspects of a construction project. Sensors, wearables, cameras, drones, and even machinery itself can be part of an IoT system in construction. These devices can transform a construction site into a smart environment, providing real-time insights and automation capabilities.

These days, sensors can be embedded in everything from materials to machinery to collect vital information on environmental conditions, structural health, and asset location. This data empowers construction companies to optimize resource allocation, ensure worker safety, and minimize waste. Mobile devices can keep project teams connected and informed, while drones provide a bird’s eye view for progress tracking and inspections. Furthermore, even robots are entering the mix, automating repetitive and hazardous tasks to improve quality and reduce costs.

IoT can also extend beyond the physical construction phase. Construction businesses can leverage smart wearables to monitor worker well-being, while environmental sensors can ensure adherence to regulations and sustainable practices. Apart from that, Building Automation Systems can optimize energy use and occupant comfort within the completed structure. By harnessing the power of IoT, construction companies gain a data-driven perspective on their operations, enabling them to make smarter decisions, reduce rework, and deliver projects on time and within budget.

Key Market Takeaways for IoT in Construction

Source: MarketsandMarkets

Firstly, construction companies are increasingly relying on new technologies due to safety concerns and the need to improve productivity. IoT sensors and wearables can be used to monitor worker well-being, fatigue levels, and environmental conditions, thereby preventing accidents and optimizing workflows. Secondly, rapid urbanization in developing regions such as Asia Pacific or APAC is fueling the construction boom.

The authorities in these countries are investing heavily in infrastructure projects and smart city initiatives, creating a massive demand for innovative solutions like IoT that can streamline complex construction processes and enhance overall efficiency. Furthermore, strict safety regulations being implemented in APAC countries are further boosting the adoption of IoT, as these technologies offer real-time monitoring and risk mitigation capabilities.

For instance, Caterpillar, a giant in construction machinery, is integrating IoT technology into its equipment, enabling remote monitoring of equipment health, optimizing maintenance schedules, and preventing costly downtime. The combination of rising safety concerns, the drive for productivity, and large-scale infrastructure projects is propelling further adoption of IoT in the construction sector.

Important Use Cases of IoT in Construction

These days, businesses are becoming increasingly aware of the potential of IoT in the construction sector. In fact, according to the Global Construction Survey, a staggering 76% of construction businesses recognize the strategic importance of integrating new technologies, with a significant focus on IoT implementations.

By deploying a network of sensors and devices, construction firms can gain real-time visibility across all project stages, right from the initial construction phase to even the post-construction operations.

So, let us discuss some interesting use cases of IoT in the construction sector,

1. Fleet Management

Managing a fleet efficiently in the construction sector can be a constant struggle, as traditional methods often lead to wasted resources, delays, and safety concerns. However, many construction firms are using IoT to mitigate this issue!

With IoT, companies can now have complete visibility into their entire fleet, including the location of each vehicle and piece of equipment, its operational status, and even its fuel efficiency. Businesses can also use automated tracking systems to eliminate guesswork and dispatch the closest resources to a job site, optimize delivery routes, and identify underutilized equipment for better allocation. Furthermore, fuel efficiency can also be improved, as IoT can help monitor and manage fuel usage better.

The advantages of IoT in fleet management can extend beyond just saving costs. Real-time data enables a more efficient workforce, leading to faster project completion times through improved dispatching and resource allocation. Additionally, knowing the fleet’s location and status enhances safety by enabling quicker response times to emergencies.

For example, a Swedish construction giant, Skanska, has already implemented an IoT-based solution to track concrete curing conditions on their projects. Sensors embedded in the concrete transmit real-time data on temperature and humidity, allowing for adjustments to optimize the curing process and ensure the structural integrity of the final product.

2. Tools, Equipment & Machine Tracking

Losing or misplacing tools and equipment can be a nightmare for construction companies. It can waste valuable time searching, disrupt workflows, and cut into profits. IoT can be an effective solution for these kinds of issues.

Construction companies can optimize their operations by equipping their tools and equipment with small, durable sensor tags that provide real-time location data. This technology eliminates the need for time-consuming searches and ensures that crews have the right tools on hand when they need them. With a quick scan using a smartphone app, workers can locate any tagged asset, minimizing downtime and boosting overall productivity.

In addition to improving efficiency, real-time tracking data can help combat theft and waste. Companies can deter opportunistic theft by knowing exactly where their equipment is located, and the potential for immediate recovery acts as a powerful deterrent. This data also empowers data-driven waste management.

For example, Leonhard Weiss GmbH & Co KG is a leading construction company in Germany that implemented an IoT platform to manage its vast equipment portfolio.

3. Machine Control

Traditionally, construction firms often have to rely on the skill and experience of grader and excavator operators to achieve precise results. While skilled operators remain crucial, IoT is ushering in a new era of construction with machine control, offering unparalleled precision and efficiency in earthwork operations.

This technology replaces the intuition of the operator with real-time data, which guides grading and excavation with unmatched precision. Machines that are equipped with sensors track their position against a pre-programmed 3D model, which feeds data to an in-cab interface. The result is perfect grades, reduced rework, and optimized machine performance. Operators can see exactly how much material needs to be moved, minimizing unnecessary passes and leading to lower fuel consumption, less wear and tear, and ultimately reduced project costs. Real-time data also empowers managers with clear insights into the progress, allowing for better monitoring and informed resource allocation.

Furthermore, advanced systems could pave the way for autonomous construction equipment. These highly sophisticated machines could handle repetitive tasks like grading or trenching with minimal human intervention. Additionally, seamless integration with Building Information Modeling software could create a closed-loop workflow. The digital design would translate directly into precise machine actions on-site, further streamlining the entire construction process.

4. Construction Site Safety

As we all know, construction sites are inherently risky, and IoT can offer a powerful solution to prioritize worker safety. For example, construction firms can use strategically placed sensors to monitor environmental conditions like extreme heat or hazardous gas leaks. This allows for immediate action to protect the health of workers. Furthermore, real-time noise level monitoring can ensure proper hearing protection, while worker location badges can guide first responders to injured workers quickly in an emergency.

Businesses can also provide workers with smart wearables that track their fatigue levels to prevent exhaustion-related accidents, detect slips and falls for immediate intervention, and even create virtual boundaries around hazardous zones.

The power of this technology lies in its proactive approach. By analyzing real-time data on worker behavior and equipment operation, construction companies can identify near-miss situations and take corrective actions before accidents occur. Targeted safety training based on real-world data can ensure that workers are prepared for the most critical risks. At the same time, the overall presence of these proactive measures fosters a heightened safety culture on the job site.

4. Project Management

Construction project management generally relies on a lot of manual inspections and isolated data, which often leads to inefficiencies and delays. However, IoT can revolutionize the way construction projects are managed.

By utilizing a network of sensors, IoT can monitor equipment health, weather conditions, and material levels to empower data-driven decisions. This translates to optimized resource allocation, scheduling adjustments to mitigate risks, and proactive maintenance to avoid equipment breakdowns that derail timelines. Furthermore, Material tracking can ensure on-time delivery, eliminating delays, while weather data allows for adjustments that prioritize worker safety.

Construction companies can also use IoT to automate workflows, replacing manual data entry with automatic reports generated from sensor data. Seamless data integration with project management software creates a single source of truth for all stakeholders, streamlining communication and reducing errors. Furthermore, real-time equipment usage data can help businesses in optimizing resource allocation, potentially reducing reliance on rented machinery.

For example, a leading international property and construction group, Lendlease, embraced an IoT platform to enhance project management on their $1.5 billion dollar Dublin Docklands project.

5. Site Monitoring

Traditional methods of site monitoring are quite outdated, as manual inspections can be slow, prone to error, and offer limited data. IoT flips the script by deploying a network of sensors throughout the site for continuous data collection.

Businesses can use these sensors to track worker movement and location for safety purposes, monitor equipment health to predict and prevent downtime, and even manage inventory levels to optimize deliveries.

- Strain gauge sensors: Embedded within structural elements, these sensors can detect excessive stress or movement, indicating potential issues.

- Vibration sensors: Monitor vibrations caused by construction activities or external factors to identify potential damage risks.

- Tilt sensors: Track any movement or tilting of structures, allowing for early detection of foundation settlement or other stability concerns.

Apart from that, environmental conditions like temperature, humidity, and dust can also be continuously monitored, ensuring a safe work environment and optimized resource use. This real-time data stream empowers construction companies to make data-driven decisions, improve efficiency through streamlined processes, and proactively address safety concerns.

Construction projects are also vulnerable to various external factors that can cause delays, safety hazards, and regulatory issues. To mitigate these risks, businesses can use IoT-based environmental monitoring tools that enable remote tracking of these factors.

By using these tools, companies can monitor weather conditions to anticipate delays, adjust schedules, or store materials as needed. Additionally, air and noise quality can be continuously monitored to ensure worker health, regulatory compliance, and minimal disruption to nearby communities. Soil moisture levels, which are crucial for foundation stability and concrete work, can also be monitored remotely to ensure optimal conditions. These proactive measures can help construction companies reduce project delays, avoid fines, and improve worker safety by enabling swift corrective actions.

Interesting Benefits of Using IoT in Construction

Now, let us discuss some of the important benefits of using IoT solutions for optimizing construction projects,

1. The Efficiency Edge: How IoT Supercharges Construction

The construction industry is often known for its tight deadlines, complex logistics, and minimal room for error. Thankfully, the IoT can help streamline construction processes and optimize resource utilization. By strategically placing sensors throughout the construction site, construction companies can obtain a constant stream of data.

This data can be used to track equipment location and usage in real-time, identify materials quickly, and monitor worker activity. This helps eliminate wasted time searching for misplaced tools, allows for proactive maintenance scheduling to prevent equipment downtime, and identifies bottlenecks in workflows for optimization.

Apart from that, construction firms can also reduce the chances of sudden equipment breakdowns, as IoT-enabled sensors can be utilized to monitor equipment health, providing valuable insights into potential failures before they occur. This allows companies to predict maintenance needs and schedule preventive maintenance during downtime, avoiding costly delays and ensuring equipment is always in top operating condition.

2. Safety First: Building a Secure Work Environment with IoT

IoT technology offers a range of tools that can help enhance safety protocols and create a more secure work environment for everyone working on the construction site.

One of the most significant ways IoT can improve safety is by equipping workers with wearable devices. These devices can track worker location, monitor vital signs in extreme conditions, and even detect falls or collisions. In case of emergencies, real-time alerts are sent to supervisors, enabling a quicker response time and potentially saving lives.

The structural integrity of a building is also very important when it comes to ensuring worker safety. IoT sensors embedded within structures can continuously monitor for signs of stress, strain, or movement. Businesses can use this technology for early detection of potential issues, such as foundation settlement or cracks in beams.

3. Building on Savings: Cost Reduction through Smart Management

Construction companies always strive to complete their projects within the allocated budget and on time. The Internet of Things can provide a strategic advantage for this purpose by facilitating advanced budgeting and cost management. By monitoring the usage of equipment, materials, and worker activity, construction companies gain valuable insights into resource allocation.

This real-time data can be used to identify inefficiencies, optimize workflows, and eliminate wasteful practices. For example, analyzing data on underutilized equipment might lead to renting instead of owning, which can lead to significant cost savings.

Manual processes and isolated information can be some major contributors to cost overruns. Businesses can use IoT to create a connected ecosystem where data flows freely between teams. This transparency allows for better decision-making, minimizes rework due to miscommunication, and ensures everyone is working towards the same goals.

4. Communication and Collaboration: Building Stronger Teams

Collaboration among multiple teams, including architects, engineers, contractors, and suppliers, is vital for the success of construction projects. Effective communication plays an important role in this process. IoT technology can bridge the communication gap by providing a platform for real-time data sharing and insights.

Construction businesses can use this technology to create a central hub where all project data is readily available. Moreover, real-time data on equipment status and material inventory, among others, will also be accessible to all stakeholders. This transparency fosters better collaboration, allows for faster issue resolution, and keeps everyone on the same page throughout the project lifecycle.

With access to a wealth of real-time data, companies will be able to make better decisions that are based on facts, not guesswork. This data can be used to optimize schedules, adjust resource allocation, and anticipate potential challenges.

Mitigating Challenges of Implementing IoT Solutions in Construction

Construction companies can indeed gain a lot of benefits from integrating IoT in their construction projects. However, integrating this new approach comes with its own set of hurdles.

So, let us discuss these key challenges and explore potential solutions to help construction businesses navigate the exciting world of IoT.

Challenge 1: Novelty and Hesitancy

Project managers and contractors might be hesitant to embrace IoT due to fear of the potential risks and downsides of a new technology.

Solution: Embrace Transparency

- Pilot Programs: Start small with pilot programs on specific aspects of a project, like real-time equipment tracking. Measurable successes can demonstrate the value proposition of IoT and build confidence for wider adoption.

- Industry Case Studies: Research and share successful implementations of IoT in construction projects. Showcasing real-world benefits can alleviate anxieties and encourage broader acceptance.

Challenge 2: Specialized Skills Requirement

Construction teams might lack the specialized skills required to handle and maintain IoT devices and the associated data analysis. This gap can hinder the proper utilization of the technology.

Solution: Invest in Knowledge Building

- Training Programs: Provide training programs to equip personnel with the necessary skills to manage and troubleshoot IoT devices. This can involve collaborating with technology vendors or developing in-house training modules.

- Partnerships: Consider partnering with companies specializing in the implementation of IoT in construction projects. Their expertise can bridge the skill gap and ensure smooth integration.

Challenge 3: Compatibility and Integration

Construction sites often use a blend of old and new technologies, which can pose a technical challenge when it comes to ensuring seamless compatibility between diverse IoT devices and legacy construction management software.

Solution: Foster Interoperability

- Open Standards: Advocate for the use of open-source IoT protocols that promote easier integration with existing systems. This allows for a more flexible approach to integrating new devices without overhauling the entire infrastructure.

- API Integration: Explore solutions that leverage Application Programming Interfaces to connect disparate systems. APIs allow for data exchange between different platforms, enabling a smooth flow of information within the construction ecosystem.

What is the Future of IoT in the Construction Sector?

The construction industry has been quiet slow in adopting new technologies despite the promise of IoT. However, there are some early adopters who are paving the way for others.

For instance, companies like Skanska and Lendlease are using IoT sensors to optimize concrete curing, monitor air quality and worker safety, and track equipment usage.

A Spark of Recognition: Awareness and Enthusiasm

There’s a growing awareness within the industry of the transformative power of digital solutions. According to a 2023 KPMG survey, 72% of construction company executives believe that the IoT will have a significant impact on their business in the next five years. As a result, many companies are now investing in digital technologies, with IoT being a major focus area for 68% of construction companies, according to a McKinsey report.

For instance, Balfour Beatty, a leading international infrastructure group, implemented an IoT-based solution to track equipment usage on a major highway project in the UK. This real-time data on equipment location and utilization allowed for improved fleet management, reduced downtime, and significant cost savings.

Pushing the Boundaries: Encouraging Exploration and Innovation

Companies like Trimble and Bosch are actively pushing for wider IoT adoption. They understand the benefits of this technology and are developing industry-specific solutions.

For instance, Bosch has introduced a wearable worker safety device that tracks location, monitors vital signs, and can detect falls. This device enables faster emergency response times and improves worker safety on construction sites.

On the other hand, Trimble’s IoT sensors for material tracking provide real-time data on inventory levels, preventing stockouts and delays. These advancements, along with ongoing research and development efforts, are continuously expanding the potential applications of IoT in the construction industry.

Top 7 IoT Platforms Used For Construction Projects

Here are some popular IoT platforms that can be used for optimizing construction projects,

1. Microsoft Azure IoT Suite

This is a comprehensive platform offering a wide range of tools for managing IoT devices, data analytics, and application development. Azure integrates seamlessly with Microsoft’s suite of productivity tools, making it a valuable option for construction companies already invested in the Microsoft ecosystem.

- Scalability and Flexibility: Azure scales to handle large amounts of sensor data from complex construction sites and integrates with various industry-specific solutions.

- Advanced Analytics: Built-in analytics tools allow you to gain insights from sensor data, optimize processes, and predict potential issues for proactive maintenance.

- Mixed Reality Integration: Azure integrates with mixed reality tools like Microsoft HoloLens, enabling remote visualization and collaboration on construction projects.

2. Bosch.IO

Bosch.IO caters specifically to construction needs, offering features for asset tracking, remote monitoring, and predictive maintenance of equipment.

- Open Connectivity: Bosch.IO supports a wide range of sensors and devices from different manufacturers, ensuring compatibility on construction sites with diverse equipment.

- Asset Management: Features for tracking equipment health, predicting maintenance needs, and optimizing utilization can reduce downtime and ensure equipment is always functional.

- Environmental Monitoring: Bosch.IO offers tools to monitor environmental conditions like air quality, noise levels, and temperature, which is crucial for maintaining a safe and healthy work environment on construction sites.

3. GE Predix Asset Performance Management

This solution from GE leverages industrial expertise to provide advanced analytics and insights for construction projects.

- Performance Optimization: GE Predix optimizes asset performance by analyzing sensor data to prevent costly downtim

- Predictive Maintenance: Predictive maintenance tools can schedule maintenance based on actual equipment usage and condition, reducing unnecessary maintenance and extending equipment life.

- Digital Twins: Predix can create digital twins of construction equipment, allowing for remote monitoring, performance simulation, and training purposes.

4. IBM Maximo Application Suite

Another industry leader, IBM, offers Maximo a comprehensive suite for managing enterprise assets. Within Maximo, the Asset Management for Construction module provides features for tracking equipment, materials, and labor, ensuring better resource utilization and project visibility.

- Work Order Management: Maximo streamlines work order creation, assignment, and tracking for construction projects, ensuring tasks are completed efficiently.

- Inventory Management: Track and manage construction materials and equipment effectively, reducing waste and ensuring availability when needed.

- Compliance Management: Maximo helps ensure construction projects comply with safety regulations and environmental standards through integrated documentation and tracking.

5. Oracle IoT Cloud Service

It is a robust platform from Oracle that offers scalability and flexibility for managing large-scale construction projects. Oracle’s platform excels in data management and analytics, allowing construction companies to gain valuable insights from sensor data collected across various project sites.

- Real-time Monitoring: Gain real-time insights into construction site activities, material usage, and environmental conditions for improved decision-making.

- Integration with Existing Systems: Oracle IoT Cloud Service integrates with existing enterprise systems like ERP and CRM, enabling a holistic view of project data.

- Advanced Security Features: Built-in security features safeguard sensitive construction site data and ensure compliance with industry regulations.

6. Cisco Kinetic for Buildings

This solution focuses on smart building applications within construction projects. Cisco Kinetic helps optimize energy use, monitor environmental conditions, and ensure occupant comfort within buildings under construction.

- Building Automation: Control and automate various aspects of construction sites, such as lighting, temperature, and access control, for improved efficiency and energy savings.

- Data-driven Insights: Collect and analyze data from connected devices to optimize resource allocation, identify potential problems, and improve overall construction site management.

- Enhanced Safety and Security: Cisco Kinetic offers features like video surveillance and access control to create a safer and more secure construction environment.

7. Siemens MindSphere

A comprehensive IoT platform from Siemens offering strong capabilities for data visualization and machine learning. MindSphere allows construction companies to leverage sensor data for predictive maintenance, identify potential issues before they escalate, and optimize resource allocation.

- Edge Computing: Process sensor data at the edge of the network, enabling faster decision-making and reduced latency for time-sensitive construction applications.

- Open APIs: Leverage MindSphere’s open APIs to integrate with various construction management software and tools for a unified workflow.

- Scalability: The platform scales to accommodate the growing data needs of large and complex construction projects.

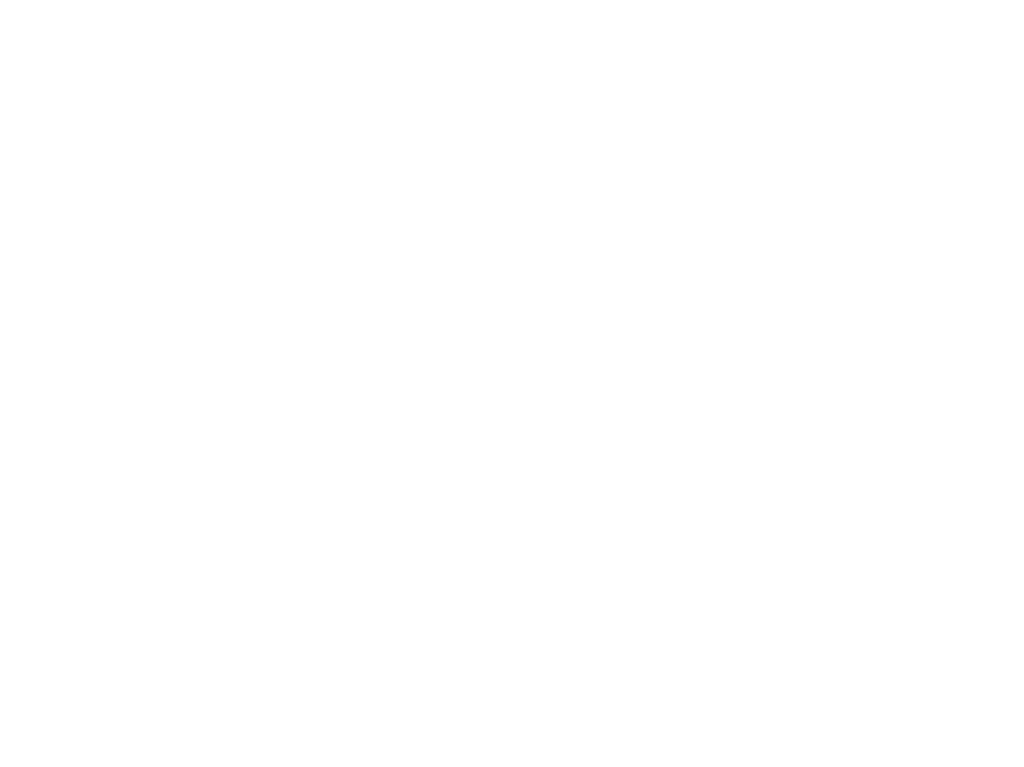

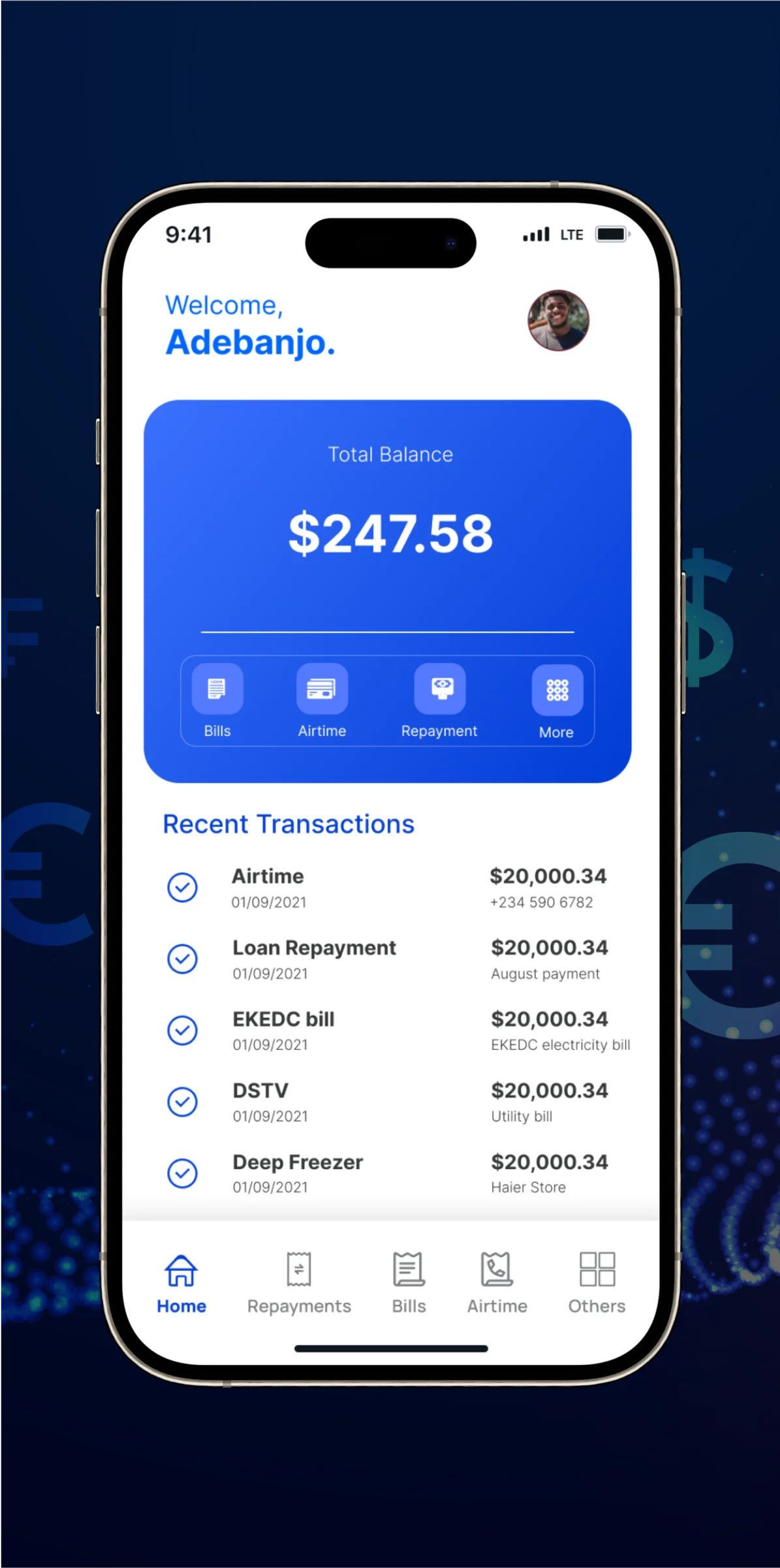

Some of Our Projects at Idea Usher

At Idea Usher, we don’t just develop apps and software – we craft solutions that empower businesses, streamline processes, and enhance user experiences.

We also love to collaborate with forward-thinking clients across a diverse range of industries, tackling unique challenges and shaping the future of technology.

Let us show you some of the interesting projects we have recently worked on,

1. Snowmatic

Our client in Canada approached Idea Usher with a vision for a revolutionary smart home solution. They sought a user-friendly platform that integrates seamlessly with Internet of Things technology to manage snow-melting devices. Their goal was to eliminate the hassle of monitoring and controlling numerous snow-melting systems spread across a property.

Idea Usher partnered with the client to bring Snowmatic to life. We developed a robust mobile application that leverages Wi-Fi provisioning to connect users to all their snow-melting devices. Snowmatic provides a centralized hub for real-time monitoring and control. Users can conveniently switch devices on or off directly through the app, ensuring optimal snow management and peace of mind, all from the comfort of their smartphones.

2. FOCO

Our client envisioned a revolutionary online shopping assistant to simplify the shopping experience and empower users to snag the best deals. Their goal was to develop a one-stop platform that tackles the common frustration of potentially missing out on lower prices elsewhere.

Idea Usher partnered with the client to turn this vision into reality. We developed FOCO, a user-friendly app that serves as a comprehensive savings hub. The app boasts a vast collection of in-app coupons and intelligent deal-finding features, all designed to empower users to make informed shopping decisions and maximize their savings. By leveraging FOCO, online shopping becomes a breeze, allowing users to confidently “Add To Cart” knowing they’ve secured the best possible price.

3. GURARIDE

In a bid to revolutionize urban mobility and promote eco-friendly transportation, our client approached Idea Usher with a vision for GURARIDE. This innovative app would provide a micro-mobility solution through a bike-sharing platform. Their goal was to tackle traffic congestion and offer a sustainable alternative for short-distance travel and errands within cities.

Idea Usher partnered with the client to bring GURARIDE to life. We developed a user-friendly app that connects users with a network of bicycles and e-scooters. GURARIDE empowers users to navigate their cities seamlessly and sustainably. Whether it’s a quick trip or a fun ride, GURARIDE offers a convenient and eco-conscious transportation option, promoting a greener future for urban environments.

Conclusion

IoT is revolutionizing construction by transforming data into actionable insights. Sensors embedded in equipment, wearables, and the environment itself provide real-time data for improved decision-making. From remote monitoring of equipment health to worker safety tracking and optimized resource allocation, IoT empowers construction businesses to enhance efficiency, reduce costs, and ensure project success. As the construction industry embraces this data-driven approach, the future promises a new era of intelligent building practices.

Looking to Implement IoT in Construction?

Ready to leverage the power of IoT to transform your construction projects? At Idea Usher, we’re your one-stop shop for implementing next-generation IoT solutions. With over 1000+ hours of coding experience in the IoT sector, our team of experts will design, integrate, and manage a customized IoT ecosystem to optimize your workflows, boost efficiency, and maximize ROI. Let Idea Usher usher your construction business into the future of intelligent building.

FAQs

Q1: What is IoT and its use cases?

A1: The Internet of Things refers to an intricate network of physical devices that collects data through embedded sensors and software. These devices, including wearables and smart appliances, can connect to the internet for remote monitoring purposes. IoT applications are vast, spanning predictive maintenance in manufacturing, environmental monitoring in agriculture, and smart home automation for increased efficiency and convenience.

Q2: How is IoT used in construction and civil engineering?

A2: IoT sensors are widely used in the construction industry to monitor environmental conditions such as temperature and humidity for optimal curing of concrete. Wearables are used to track worker location and vitals in order to enhance safety. Additionally, equipment equipped with IoT technology allows for remote monitoring, predicting maintenance needs, and preventing costly downtime. Drones equipped with sensors are used to map and inspect construction sites, which improves surveying and progress tracking. Overall, the use of IoT technology increases efficiency, reduces risk, and improves project management in construction and civil engineering.

Q3: What is the working principle of IoT?

A3: IoT devices use integrated sensors to collect data, which is then transmitted wirelessly through technologies that can include Wi-Fi, Bluetooth, or cellular networks to a cloud platform. The cloud processes the data, providing real-time insights and enabling remote control or automated actions based on pre-defined parameters. For example, if an IoT sensor detects high pressure in a pipe, it can trigger an automated shut-off valve to prevent a burst.

Q4: What are the four types of IoT?

A4: The world of IoT can be broadly categorized into four groups depending on their function and communication style. Consumer IoT focuses on everyday conveniences in homes with the help of smart appliances and wearables. Industrial IoT deals with heavy-duty tasks in factories and power plants using robust networks. Infrastructure IoT manages city systems like traffic lights with wide-area coverage. Finally, Commercial IoT bridges the gap and brings smart technology to businesses such as shops and hospitals, adapting its communication style to their specific requirements.