- The Present Situation of Technology in Manufacturing

- Key Features of Manufacturing Mobile Apps

- Benefits of Mobile Apps in Manufacturing

- Stats Related to Adoption of Mobile Apps in Manufacturing

- Building a Mobile App in Manufacturing

- Challenges and Considerations in Manufacturing Mobile App Development

- Examples Of Apps In the Manufacturing Industry

- Conclusion:

- FAQ

In today’s rapidly evolving digital landscape, the manufacturing industry is harnessing the power of mobile app development to revolutionize its processes, enhance efficiency, and stay competitive in a dynamic market. This blog is your gateway to the world of Manufacturing Mobile App Development, where we explore how these innovative applications are reshaping the manufacturing sector from the ground up.

Manufacturing, a field long associated with industrial machinery and traditional practices, is undergoing a remarkable transformation fueled by cutting-edge mobile technology. Mobile apps are no longer just for communication or entertainment; they have emerged as powerful tools that enable manufacturers to streamline operations, optimize resource management, and embrace the era of Industry 4.0.

This blog serves as your comprehensive guide to understanding the pivotal role of mobile apps in manufacturing.

- The Present Situation of Technology in Manufacturing

- Key Features of Manufacturing Mobile Apps

- Benefits of Mobile Apps in Manufacturing

- Stats Related to Adoption of Mobile Apps in Manufacturing

- Building a Mobile App in Manufacturing

- Challenges and Considerations in Manufacturing Mobile App Development

- Examples Of Apps In the Manufacturing Industry

- Conclusion:

- FAQ

The Present Situation of Technology in Manufacturing

In the world of manufacturing, while some aspects of technology have seen significant advancements, there exists a conspicuous gap where technological prowess is lacking. Although certain segments of the industry may boast cutting-edge machinery dedicated to specific production tasks, they often fall short in terms of essential infrastructure, particularly cloud integration and systems compatibility necessary for comprehensive data analysis and product development enhancement.

This deficit in technological adoption is a persistent issue, leaving manufacturing organizations trailing behind their counterparts in other sectors. With the onset of the Fourth Industrial Revolution, often referred to as Industry 4.0, manufacturers are presented with an urgent need to bridge this gap to stay competitive in the evolving landscape.

Surprisingly, only a mere 20.7% of manufacturing entities consider themselves “highly prepared” to tackle the emerging business models that the Fourth Industrial Revolution ushers in. However, there is a notable willingness among manufacturers, with 81% expressing readiness to invest in novel digital technologies aimed at enhancing productivity.

As we delve deeper into the realms of manufacturing digital transformation statistics, it becomes clear that the industry is at a pivotal juncture, where strategic technology adoption can be the key to ushering in a new era of efficiency and innovation. In this blog, we explore how manufacturing mobile app development can play a crucial role in this transformation.

Key Features of Manufacturing Mobile Apps

Manufacturing mobile apps are designed to address the unique needs and challenges of the industry. They offer a wide range of features that enhance efficiency, streamline processes, and improve overall productivity. Here are the key features that make these apps indispensable for modern manufacturers:

Data Analytics and Reporting:

In the manufacturing sector, data is a valuable asset. Mobile apps equipped with robust data analytics capabilities provide real-time insights into operations. They gather data from various sources, such as machinery, sensors, and production lines, and transform it into actionable information. This enables manufacturers to make informed decisions promptly.

Data analytics within these apps offer benefits like predictive maintenance, quality control, and demand forecasting. By identifying patterns and trends, manufacturers can optimize production schedules, reduce downtime, and allocate resources efficiently. Additionally, customizable reporting tools empower managers to track performance, identify bottlenecks, and assess the overall health of their operations.

IoT Integration:

The Internet of Things (IoT) has revolutionized manufacturing by connecting machinery, equipment, and devices to the internet. Mobile apps in manufacturing often integrate with IoT sensors and devices. This integration enables real-time monitoring and control of equipment, allowing manufacturers to detect issues before they lead to downtime or costly breakdowns.

IoT integration provides data on machine health, energy consumption, and production efficiency. Manufacturers can remotely adjust machine settings, track equipment performance, and receive automated alerts for maintenance needs. This proactive approach to equipment management significantly reduces operational costs and improves overall productivity.

Supply Chain Visibility:

Manufacturing mobile apps extend their reach beyond the factory floor by enhancing supply chain visibility. These apps offer features that enable manufacturers to monitor the movement of materials and products in real-time. GPS tracking, barcoding, and RFID technology integration provide accurate and up-to-date information about the location and status of inventory.

Supply chain visibility empowers manufacturers to optimize inventory levels, minimize stockouts, and reduce excess inventory costs. It also enables efficient order fulfillment, on-time deliveries, and better coordination with suppliers and distributors. Ultimately, this feature contributes to improved customer satisfaction and loyalty.

Predictive Maintenance:

Unplanned equipment downtime can be a significant cost for manufacturers. Predictive maintenance, facilitated by mobile apps, uses data analysis and machine learning algorithms to predict when equipment is likely to fail. By identifying potential issues in advance, manufacturers can schedule maintenance at optimal times, reducing disruption to production.

Mobile apps with predictive maintenance capabilities collect data from sensors and equipment, analyzing it to detect anomalies and patterns indicative of impending failures. This proactive approach not only extends the lifespan of machinery but also minimizes maintenance costs and production interruptions.

Mobile Security and Compliance:

Manufacturing deals with sensitive data, including intellectual property, customer information, and compliance regulations. Mobile apps for manufacturing prioritize security and compliance. They incorporate encryption, user authentication, and secure data storage to protect critical information from unauthorized access and cyber threats.

Moreover, these apps assist manufacturers in adhering to industry-specific regulations and standards. They facilitate document management, audit trails, and compliance reporting, ensuring that the organization remains compliant with quality, safety, and environmental requirements.

Incorporating these key features into manufacturing mobile apps equips businesses with the tools needed to thrive in a competitive and rapidly evolving industry. These apps not only enhance efficiency and productivity but also contribute to long-term sustainability and growth.

Benefits of Mobile Apps in Manufacturing

Mobile apps have emerged as powerful tools in the manufacturing industry, driving significant improvements in efficiency, productivity, and overall operations. These apps address various aspects of manufacturing, from production processes to quality control and customer engagement. Here are the key benefits of integrating mobile apps into manufacturing operations:

Improved Efficiency and Productivity:

Here are some points to explain it throughly

1. Real-time data access:

Mobile apps provide manufacturing teams with real-time access to critical data and information, regardless of their location. This capability is especially valuable for managers, technicians, and operators who need up-to-the-minute insights into production processes. Real-time data access allows for faster decision-making and immediate responses to issues or changes on the shop floor. This results in reduced downtime, improved resource utilization, and better overall efficiency.

2. Task automation:

Mobile apps in manufacturing excel at automating routine and time-consuming tasks. They can streamline workflows by automating data entry, reporting, and communication processes. For instance, automated data collection and reporting eliminate the need for manual record-keeping, reducing the risk of errors and ensuring data accuracy. Task automation also frees up employees to focus on more valuable, strategic activities, ultimately boosting productivity.

Enhanced Inventory Management:

1. Inventory tracking and control:

Mobile apps offer sophisticated inventory tracking and control features. Manufacturers can monitor inventory levels, track item locations, and receive real-time updates on stock movement. This visibility into inventory status helps prevent stockouts, reduce excess inventory costs, and optimize reorder points. Additionally, accurate inventory data ensures that production lines have the necessary materials, minimizing production delays.

2. Demand forecasting:

Mobile apps equipped with demand forecasting capabilities use historical data, market trends, and predictive analytics to project future demand accurately. Manufacturers can adjust production schedules and inventory levels based on these forecasts, avoiding overproduction or underproduction. By aligning production with actual demand, manufacturers reduce waste, improve resource utilization, and enhance overall efficiency.

Quality Control and Assurance:

1. Inspection and reporting:

Quality control is paramount in manufacturing. Mobile apps facilitate quality inspections and reporting by providing standardized checklists and digital forms. Quality inspectors can document findings, capture photos, and record measurements directly on their mobile devices. This digital approach ensures consistency, accuracy, and traceability in quality assurance processes. Any deviations or non-conformities can be identified and addressed promptly, reducing defects and rework.

2. Compliance monitoring:

Manufacturers must adhere to industry-specific regulations and quality standards. Mobile apps assist in compliance monitoring by incorporating compliance checklists, audit trails, and documentation capabilities. These apps ensure that all necessary quality and safety protocols are followed, helping manufacturers avoid regulatory fines and maintain their reputation for delivering high-quality products.

Workforce Empowerment:

1. Training and skill development:

Mobile apps enable manufacturers to provide on-the-go training and skill development opportunities to their employees. Interactive training modules, videos, and documentation can be accessed via mobile devices, allowing workers to enhance their skills and knowledge conveniently. This fosters a skilled and adaptable workforce, which is essential in a rapidly evolving industry.

2. Employee engagement:

Engaged employees are more productive and committed to their work. Mobile apps can include features that enhance employee engagement, such as communication tools, feedback mechanisms, and recognition programs. By fostering a sense of belonging and involvement, manufacturers can boost employee morale and motivation, leading to higher productivity levels.

In summary, mobile apps are transforming the manufacturing landscape by delivering tangible benefits across various aspects of the industry. From optimizing production processes to enhancing quality control and customer engagement, these apps empower manufacturers to stay competitive, efficient, and customer-focused in today’s dynamic market.

Stats Related to Adoption of Mobile Apps in Manufacturing

As the world of app development continues to evolve, it’s essential to stay informed about key statistics and trends that shape the landscape. Here are some noteworthy insights:

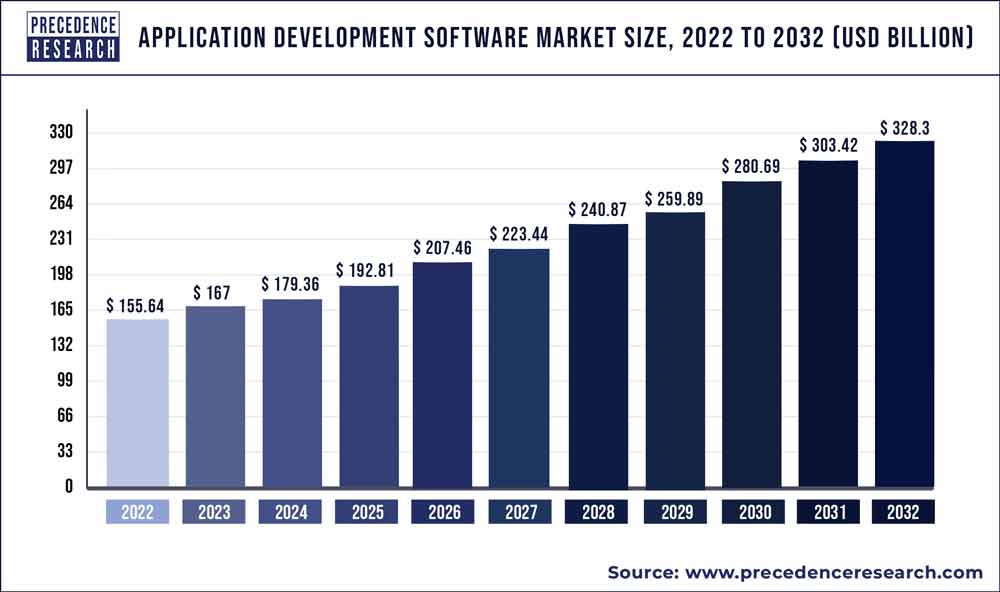

1. Revenue Growth:

with projections indicating that it’s set to nearly double in size over the next decade. In 2022, the market was valued at USD 155.64 billion, but by 2032, it’s expected to reach a staggering USD 328.3 billion. This remarkable growth, at a compounded annual rate of 7.8% from 2023 to 2032, reflects the increasing demand for innovative software solutions across industries. As businesses and individuals alike continue to embrace digital transformation, this expanding market underscores the pivotal role that application development software plays in shaping our technological landscape. It’s not just a market; it’s a testament to the boundless possibilities of human creativity and technological advancement.

2. Popular Programming Languages:

In the realm of app development, programming languages play a pivotal role. As of 2022, JavaScript and HTML/CSS stand out as the most commonly used languages, with over 65% of developers utilizing JavaScript and approximately 55% working with HTML/CSS. Python, SQL, and TypeScript follow closely in popularity.

3. Cloud Platforms:

The choice of cloud platforms significantly impacts app development. In 2021, AWS (Amazon Web Services) emerged as the top choice, with a remarkable 40.35% of developers expressing interest in working with it. Google Cloud Platform secured the second position, garnering the interest of 22.56% of surveyed software developers.

Back in 2014, the manufacturing landscape underwent a significant transformation with the adoption of mobile apps. A survey conducted by Canvas during that year unveiled compelling statistics that reflected the industry’s recognition of mobile apps as game-changers:

– Inspections:

A substantial 48% of manufacturers had already embraced mobile apps to streamline their inspection processes. This adoption indicated a shift towards more efficient and data-driven quality control measures.

– Work Orders:

36% of manufacturers had integrated mobile apps into their work order procedures. This marked a departure from traditional paper-based work orders, signifying a transition to digital workflows.

– Checklists:

Approximately 28% of manufacturers had recognized the value of mobile apps in creating and managing checklists. This adoption facilitated better organization and compliance with essential tasks.

– Surveys:

23% of manufacturers had harnessed mobile apps for conducting surveys, enabling them to gather valuable insights and feedback efficiently.

– Invoices:

15% of manufacturers had made the switch to mobile apps for handling invoices, streamlining financial transactions and record-keeping.

– Inventory:

8% of manufacturers had leveraged mobile apps to manage their inventory, marking a transition towards more agile and data-driven inventory management practices.

These statistics from 2014 showcased the manufacturing industry’s early recognition of the transformative potential of mobile apps, setting the stage for continued innovation and adoption in subsequent years.

Building a Mobile App in Manufacturing

The process of developing a mobile app in manufactuting is a comprehensive undertaking that involves multiple stages, each crucial to the app’s success. In this section, we’ll explore these stages in detail, from initial planning to post-launch support and optimization, ensuring that your manufacturing app is not just functional but excels in meeting the specific needs of your industry.

Planning and Requirements

Identifying Goals, Objectives, and User Personas: The foundation of any successful manufacturing mobile app project lies in a well-defined set of goals and objectives. What do you aim to achieve with this app? Are you looking to streamline production processes, enhance inventory management, improve quality control, or empower your workforce with tools for better productivity? Defining clear objectives is essential as they serve as a roadmap for the entire project.

User personas are equally critical. Understanding the needs, preferences, and pain points of your app’s potential users allows you to tailor the app’s features and user experience to their specific requirements. These personas could include factory floor workers, supervisors, quality control teams, inventory managers, and even customers if the app has external-facing features.

Development Process

Choosing the Right Development Approach and Team: Manufacturing mobile apps can be developed using various approaches, each with its own set of advantages and considerations. The primary options include native, hybrid, or cross-platform development.

– Native:

Native apps are developed for a specific platform (e.g., iOS or Android) using platform-specific languages (Swift for iOS, Java/Kotlin for Android). They offer the best performance and access to device features but require separate development efforts for each platform.

– Hybrid:

Hybrid apps use web technologies (HTML, CSS, JavaScript) and a single codebase to run on multiple platforms. They offer a compromise between performance and development effort but may have limitations in accessing device features.

– Cross-platform:

Cross-platform development frameworks like React Native and Flutter allow you to write code once and deploy it on multiple platforms. They strike a balance between performance and code reusability.

The choice of development approach depends on factors such as your budget, timeline, desired platform compatibility, and the specific features your app requires. It’s crucial to weigh these factors carefully and select an approach that aligns with your project’s goals.

Selecting the right development team or partner is equally important. Look for a team with experience in creating apps for the manufacturing sector. Their domain knowledge can be invaluable in understanding the unique challenges and requirements of your industry.

Testing and Quality Assurance

Thorough testing and quality assurance are non-negotiable steps in the app development process, ensuring that your manufacturing app functions flawlessly and meets the highest standards of performance and security.

– Functionality Testing: This phase involves testing every aspect of the app’s functionality to ensure it works as intended. It includes user interface testing, data input validation, and verifying that all features perform their intended tasks.

– Performance Testing: Manufacturing apps often handle large volumes of data and complex processes. Performance testing assesses how the app handles these loads, ensuring it remains responsive and efficient even under heavy usage.

– Security Testing: Security is paramount, especially in the manufacturing sector, where sensitive data is often involved. Security testing identifies vulnerabilities and weaknesses in the app’s code, infrastructure, and data storage, helping prevent data breaches and unauthorized access.

– Compatibility Testing: Manufacturing apps may need to run on a variety of devices and operating systems. Compatibility testing ensures that the app functions correctly on different platforms and screen sizes, delivering a consistent user experience.

– Usability Testing: Usability testing involves gathering feedback from real users to assess the app’s user-friendliness and identify areas for improvement. This feedback can be invaluable in fine-tuning the app’s design and flow.

Deployment and Launch

Once your manufacturing app has passed through the rigorous testing phase and is deemed ready for prime time, it’s time to move on to deployment and launch. This phase involves several key steps:

– Uploading to App Stores: If your app is intended for public use, it needs to be made available on app stores like the Apple App Store and Google Play Store. Each platform has its specific requirements and guidelines for app submission, and adhering to these is essential for a smooth launch.

– Announcing the Launch: Letting your target audience know about your app’s availability is crucial. This can be achieved through various marketing efforts, including email campaigns, social media announcements, press releases, and notifications to existing customers.

– User Support: Providing comprehensive user support is vital during and after the launch. Be prepared to address user queries, troubleshoot issues, and offer guidance on how to use the app effectively. A well-prepared support team or help center can significantly enhance the user experience.

– Training Resources: Depending on the complexity of your manufacturing app, offering training resources to users can be immensely beneficial. This could include instructional videos, user guides, and online tutorials to help users make the most of the app’s features.

Post-Launch Support and Optimization

The launch of your manufacturing app marks the beginning of its lifecycle, not the end. Continuous support and optimization are essential for long-term success:

– User Support: Post-launch support should continue to address user questions, issues, and feedback promptly. User satisfaction plays a significant role in the app’s success and adoption.

– Data Analytics: Monitoring app usage through data analytics is crucial for gaining insights into user behaviour. By analyzing data, you can identify trends, spot areas of improvement, and make data-driven decisions to enhance the app.

– Regular Updates: Mobile platforms evolve, and user expectations change. Regular updates to your app are necessary to keep it compatible with the latest platform versions, ensure security, and introduce new features based on user feedback and industry developments.

– Performance Optimization: Performance can degrade over time due to factors like increased data volumes or changes in the operating environment. Continuous performance optimization efforts are essential to maintain a seamless user experience.

– Security Updates: Cybersecurity threats are ever-present. Regular security updates and patches are essential to protect sensitive data and maintain user trust.

Challenges and Considerations in Manufacturing Mobile App Development

Building a manufacturing mobile app comes with its set of challenges and considerations, many of which are unique to the manufacturing industry. Addressing these challenges and considerations is essential to ensure the success and long-term viability of your app.

Data Security and Privacy

Data security and privacy are paramount in the manufacturing sector, where sensitive information about processes, products, and operations is often involved. Protecting this data from unauthorized access, breaches, and cyber threats is a top priority. When developing a manufacturing app, it’s crucial to:

To safeguard sensitive manufacturing data, the app must implement robust encryption for data in transit and at rest, ensuring that all communication between the app and backend systems is encrypted.

Additionally, enforce stringent user authentication measures to verify user identities and restrict access exclusively to authorized personnel. Compliance with industry-specific regulations is paramount in the manufacturing sector, where strict data security and privacy standards apply. Ensure your app aligns seamlessly with these requirements to avoid legal complications and potential penalties.

Integration with Existing Systems

Manufacturing facilities heavily rely on diverse existing systems like ERP (Enterprise Resource Planning) software, inventory management systems, and production control systems. Seamless integration of your mobile app with these systems is essential to enable real-time data exchange and streamline processes.

Key considerations encompass API compatibility, ensuring that your app can effortlessly connect to existing systems through well-defined APIs (Application Programming Interfaces). Implement robust mechanisms for data synchronization between the mobile app and backend systems to maintain data consistency. Given that manufacturing often involves legacy systems lacking modern integration capabilities, it’s crucial to devise strategies for bridging the gap between these legacy systems and modern technologies.

Scalability

Manufacturing mobile apps must be designed with scalability in mind to accommodate potential user growth and increased data volume. Key considerations encompass a scalable server infrastructure, ensuring that the backend can efficiently handle heightened traffic and data processing demands.

Regular performance optimization and monitoring are crucial to prevent slowdowns or system failures as the user base expands. Additionally, conducting load testing is essential to identify and address potential bottlenecks, ensuring the app can seamlessly handle a surge in users without compromising performance.

User Adoption and Training

Ensuring the successful adoption of your manufacturing app among employees is pivotal to its effectiveness. Overcoming resistance to change and facilitating user proficiency are essential components of this process. To achieve this, provide comprehensive user training resources and support, enabling users to become proficient in app utilization. Additionally, foster a culture of user feedback, actively encouraging and integrating their suggestions for continuous improvement into app updates. Implementing effective change management strategies is vital to help employees transition seamlessly to using the app as part of their daily workflows.

Maintenance and Updates

Mobile app development extends beyond the initial launch, necessitating ongoing maintenance and updates to ensure the app remains relevant and functional. This encompasses timely bug fixing to address reported issues, preserving a positive user experience.

Staying current with platform-specific updates (e.g., iOS, Android) is crucial to maintain compatibility and security. Furthermore, ongoing development efforts should focus on feature enhancements, incorporating new capabilities and improvements driven by user feedback and evolving industry demands.

Examples Of Apps In the Manufacturing Industry

In the dynamic landscape of the manufacturing industry, the integration of mobile apps has spurred remarkable transformations. These real-world examples showcase the diverse applications of mobile technology, catering to a wide range of manufacturing needs, from large enterprises to small businesses.

1. Oracle Fusion Cloud ERP:

Designed for mid to enterprise-level businesses, Oracle Fusion Cloud ERP offers a comprehensive suite of solutions. It facilitates efficient management of risk, supply chain, procurement, and project management processes. This cloud-based ERP suite empowers organizations to streamline administrative tasks and enhance overall operational efficiency.

2. Opstech:

Opstech provides manufacturing execution software tailored for factories. Its focus is on managing and monitoring manufacturing processes, personnel, and machinery while ensuring compliance with quality standards. Opstech aids administrators in visualizing workflows for individual products, optimizing production, and maintaining quality control.

3. Intellect QMS:

With a strong emphasis on configurability, Intellect QMS offers highly intuitive quality management software. It enables businesses to meet FDA compliance and ISO standards, driving operational excellence and boosting productivity. This robust software suite is adaptable to the specific quality control needs of manufacturers.

4. Salesforce Sales Cloud:

Salesforce Sales Cloud is a cloud-based CRM and sales automation solution that empowers sales teams to close deals effectively. It provides insights into the health of the business, making it an ideal choice for manufacturing organizations looking to optimize their sales processes.

5. AutoCAD:

AutoCAD is a renowned 2D and 3D design and drafting platform. Widely used in manufacturing, it supports automated design tasks, including 2D drafting, drawing, annotation, 3D modeling, and visualization. AutoCAD aids in creating precise and detailed design plans.

6. UpKeep:

UpKeep is a mobile maintenance management software (CMMS) designed for manufacturing. It enables users to efficiently manage their teams, assign work orders, and synchronize devices. This mobile solution simplifies maintenance tasks, ensuring equipment reliability and minimizing downtime.

7. GanttPRO:

GanttPRO is an online Gantt chart software that serves as a powerful project management tool for manufacturing organizations globally. It provides a visual representation of project timelines, aiding in project planning, scheduling, and execution.

These examples illustrate the versatility and impact of mobile apps in the manufacturing sector. From optimizing operational processes to enhancing quality control and streamlining project management, mobile apps offer valuable solutions tailored to the unique needs of manufacturers. Whether you operate a large-scale enterprise or a small business, these applications demonstrate the transformative potential of mobile technology in the manufacturing industry.

Conclusion:

In conclusion, the adoption of mobile apps in the manufacturing industry has proven to be a transformative journey. Manufacturing mobile apps offer real-time data access, task automation, enhanced inventory management, quality control, workforce empowerment, and improved customer engagement. They bridge the gap between legacy systems and modern technology, ensuring seamless integration and scalability. However, these benefits come with considerations such as data security, user adoption, and ongoing maintenance.

As manufacturers worldwide embrace the digital era, mobile app development remains at the forefront of this transformation. To thrive in an increasingly competitive landscape, companies must leverage these powerful tools to enhance their operations.

At Idea Usher, we understand the unique challenges and opportunities in the manufacturing sector. Our expertise in mobile app development can help your organization harness the full potential of these applications.

Let us be your partner in embracing the limitless possibilities of manufacturing mobile app development.

FAQ

Q. What are the primary benefits of using mobile apps in the manufacturing industry?

Mobile apps in manufacturing offer benefits such as real-time data access, task automation, improved inventory management, quality control, and enhanced customer engagement. They can boost efficiency, productivity, and competitiveness.

Q. How can manufacturers ensure the security of sensitive data within their mobile apps?

Manufacturers can enhance security by implementing robust encryption, enforcing user authentication, and complying with industry regulations. Regular security audits and updates are also essential to protect against evolving threats.

Q. How much does it cost to manufacture an app?

App development costs vary widely. The price depends on features, platforms, and location of the app as well as complexity. You can get a better understanding of it after getting a free consultation with a company like IdeaUsher.

Q. What are the key stages of app development?

The four main stages are planning and requirements, development, testing and QA, and deployment. Each phase is essential for creating a successful app.

Q. Which technology is best for app development?

The choice depends on your app’s requirements. Native offers maximum performance, hybrid combines efficiency, and cross-platform ensures broader reach with some trade-offs.

Yuvraj Singh