Business operational challenges tend not to struggle from lack of effort but from how data, workflows, and decisions are spread across disconnected systems that do not scale together. As organizations grow, managing finance, inventory, procurement, HR, and reporting through isolated tools creates delays, errors, and limited visibility. These challenges are what make an ERP system for business operations a foundational requirement rather than a back-office upgrade.

Implementing an ERP system is less about installing software and more about aligning how the business actually runs. Processes need to be mapped accurately, data structures must support cross-functional use, and integrations have to reflect real operational dependencies. The success of an ERP initiative depends on how well system design, change management, and execution planning come together to support day-to-day operations without disruption.

In this blog, we explain how to implement an ERP system for business operations by outlining key planning steps, system components, and practical considerations involved in deploying a solution that supports efficiency, visibility, and long-term operational stability.

What is an ERP System for Business Operations?

Enterprise Resource Planning (ERP) is a comprehensive system that unifies and automates core functions like finance, HR, supply chain, procurement, inventory, sales, and customer service into one shared database. It eliminates silos, providing real-time data, improving performance monitoring, reducing manual effort, and streamlining processes with greater accuracy.

More than software, an ERP system serves as the operational backbone of modern enterprises by centralizing data into unified dashboards and reports. Available on-premises or in the cloud, it improves collaboration, reduces errors, streamlines workflows, controls costs, and supports scalable business growth.

When Does a Business Need an ERP System?

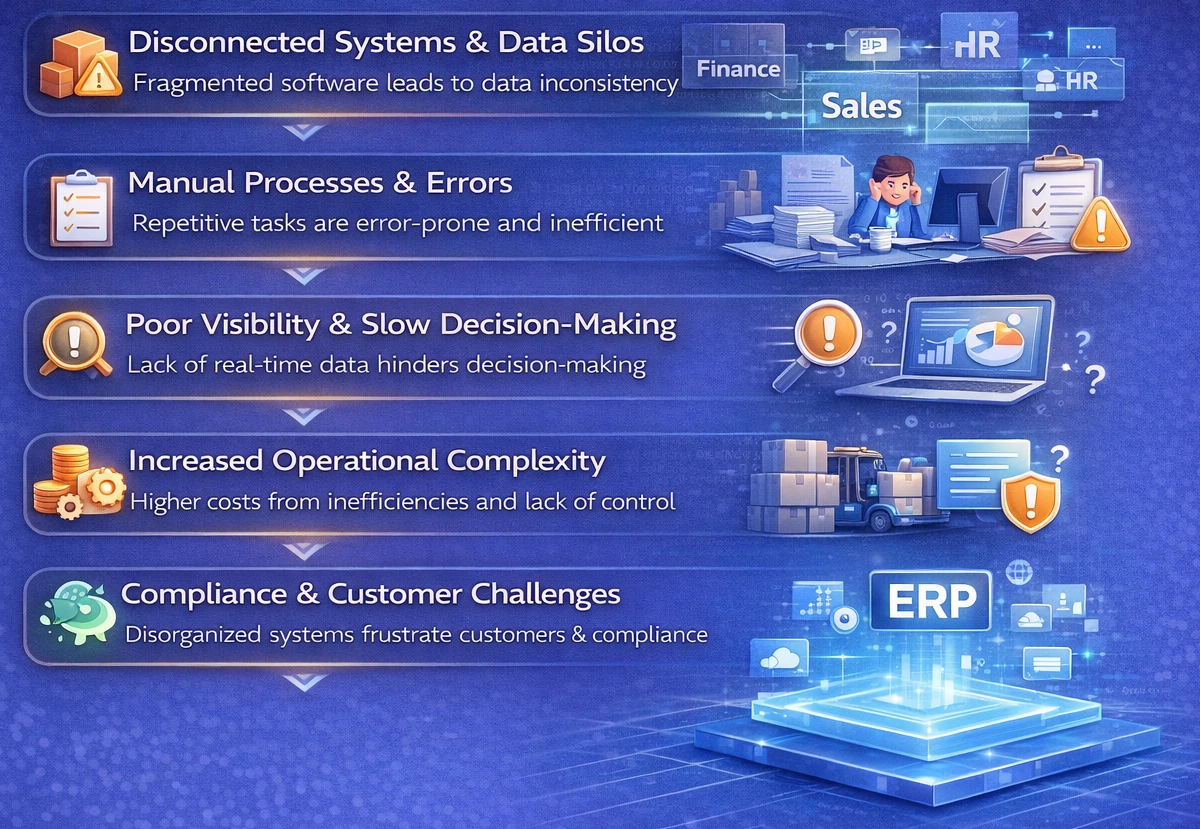

As organizations scale, managing core business operations across fragmented systems becomes inefficient, signaling the need for an ERP system. This overview explores when an ERP system for business operations becomes a strategic fit.

1. Disconnected Systems and Data Silos

Separate software for finance, sales, inventory, HR, and other functions leads to inconsistent data, unreliable collaboration, slow processes, and scaling challenges. A unified ERP consolidates data into a single source of truth, breaking down silos.

2. Manual Processes and Errors

When teams spend excessive hours on repetitive manual tasks like data entry, reconciliation, and reporting, your current tools are insufficient. These processes are prone to errors and waste valuable time. ERP automates key workflows, reducing errors and enhancing productivity.

3. Poor Visibility and Slow Decision-Making

Effective decision-making needs real-time, accurate data. Slow or inconsistent reporting hampers visibility. ERP systems offer centralized dashboards and analytics for real-time insights.

4. Increased Operational Complexity

This is driven by rising costs of goods sold (COGS) from poor inventory management, excess stock costs, and waste from inefficiencies. An ERP system fixes this with better inventory control, streamlined procurement, and resource analytics, targeting hidden costs.

5. Compliance and Customer Challenges

Internal disorganization affects customers, causing inaccurate shipment promises, delays, and poor communication from disconnected systems. Implementing an ERP enhances customer data management, integrates order-to-cash cycles, and improves process connectivity, boosting satisfaction.

How Does an ERP System Improve Business Operations?

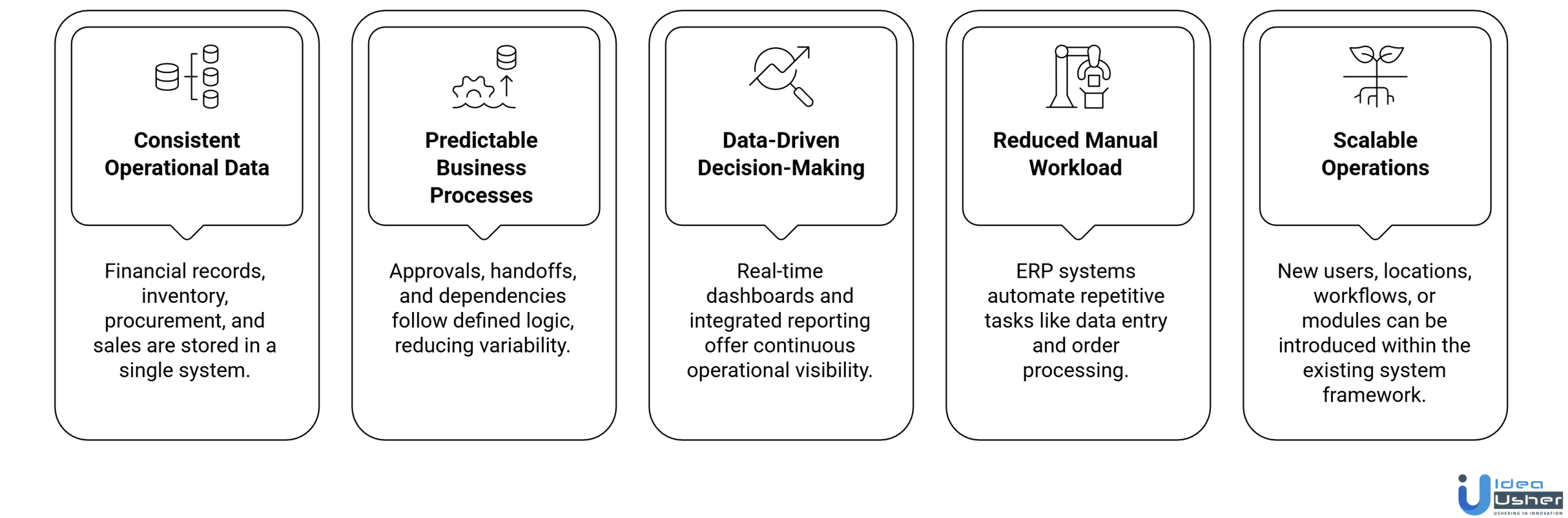

Once an ERP system is implemented, its value is realized through structural improvements in how business operations are executed, monitored, and scaled. Rather than addressing when ERP is needed, this section focuses on what changes operationally after ERP becomes part of the organization’s core infrastructure.

1. Consistent Operational Data

ERP systems unify transactional and operational data into one model. Financial records, inventory, procurement, and sales are stored in a single system, ensuring consistency across departments. This enables teams to use accurate, real-time info for execution and reporting without manual reconciliation.

2. Predictable, Repeatable Business Processes

Embedding workflows into daily operations enables ERP systems to replace ad-hoc processes with structured paths. Approvals, handoffs, and dependencies follow defined logic, reducing variability. This predictability improves efficiency and helps organizations manage growing transaction volumes.

3. Data-Driven Decision-Making

ERP systems with real-time dashboards and integrated reporting offer continuous operational visibility. Leaders no longer rely on delayed or manual reports but get immediate insights into key metrics, allowing quicker decisions and proactive adjustments.

4. Reduced Manual Workload

ERP systems automate repetitive tasks like data entry, reconciliations, order processing, and reporting. This reduces manual work, minimizes errors, and lets teams focus on higher-value activities instead of admin tasks.

5. Scalable Operations

As businesses grow, ERP systems support increased complexity without requiring fundamental changes to operational structure. New users, locations, workflows, or modules can be introduced within the existing system framework. This ensures scalable operations without fragmentation or loss of control.

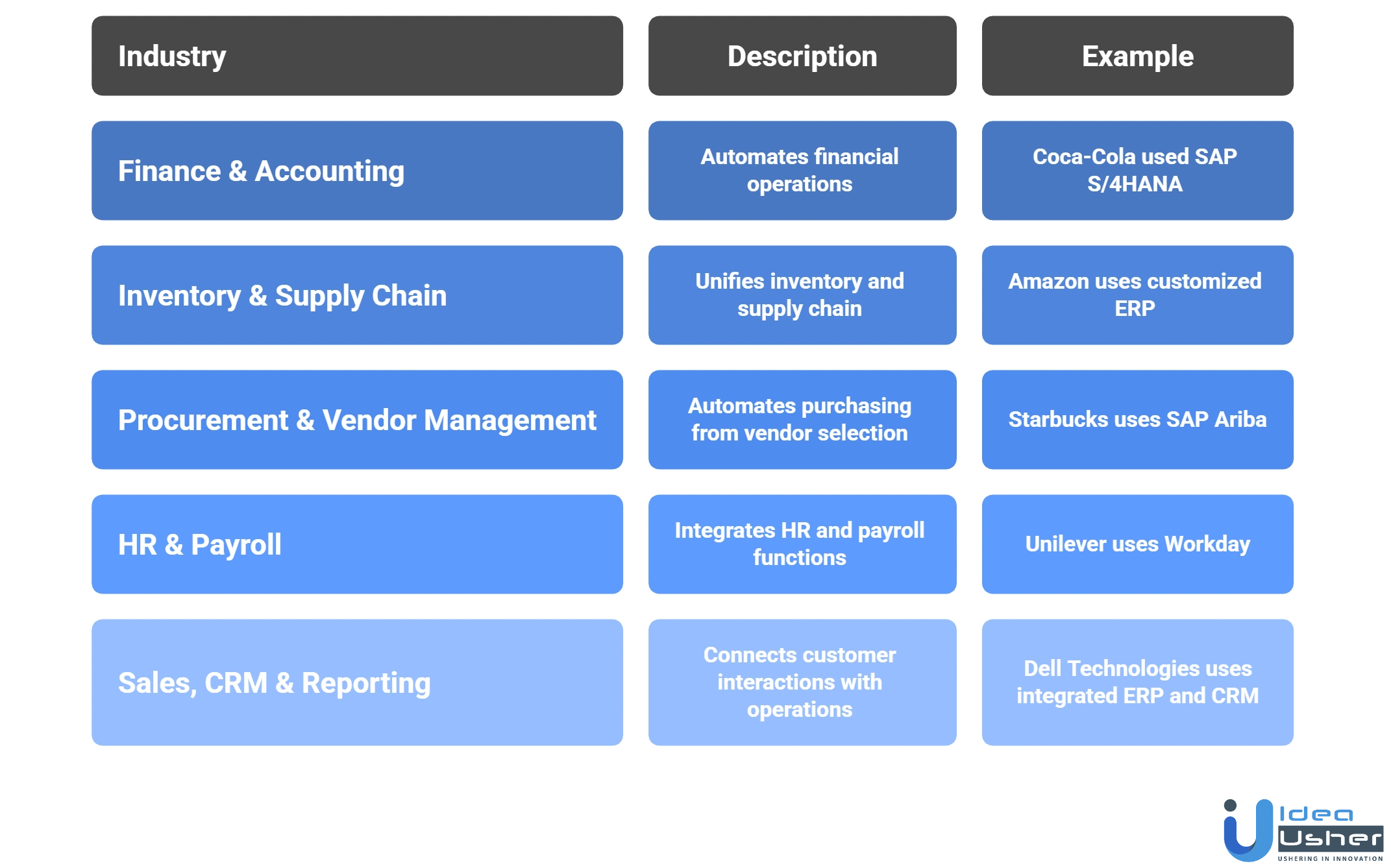

Key Industries Using ERP System for Business Operations

An ERP system integrates essential business functions into a unified platform, enabling seamless data flow, operational efficiency, and consistent visibility across departments.

1. Finance & Accounting

The finance and accounting module automates operations like ledger management, accounts payable and receivable, budgeting, and reporting. It centralizes financial data to provide real-time cash flow, simplify compliance and audits, and eliminate manual reconciliations.

Example: Coca-Cola used SAP S/4HANA to consolidate global finances, reducing book closing from weeks to days. Real-time visibility supports faster decisions and simpler compliance across 200+ countries.

2. Inventory & Supply Chain

ERP platforms unify inventory control and supply chain management, tracking stock, managing warehouses, and coordinating logistics from procurement to delivery. This integration ensures accurate forecasts, optimized stock, reduced costs, and improved order fulfillment.

Example: Amazon uses a customized ERP integrated with warehouse systems to manage real-time inventory across global fulfillment centers. It dynamically routes stock based on demand and proximity, optimizing delivery speed and storage costs, especially during Prime Day.

3. Procurement & Vendor Management

The procurement module automates purchasing from vendor selection to invoice processing. It improves vendor relationships, enforces policies, and provides transparency in contracts and spending, helping control costs and reduce risks.

Example: Starbucks uses SAP Ariba to manage global procurement across 30,000+ stores. The platform automates purchasing, compares supplier pricing during market changes, and tracks vendor performance to maintain quality and negotiate better terms.

4. HR & Payroll

ERP systems integrate HR and payroll functions, consolidating employee records, tracking attendance, performance, salary, and benefits. This unification streamlines administration, boosts compliance, and enhances workforce planning.

Example: Unilever uses Workday to manage HR for 150,000+ employees across 190 countries. The platform supports compliance, enables internal talent identification through analytics, and helps manage hybrid work and office space planning.

5. Sales, CRM & Reporting

An ERP’s sales and CRM tools connect customer interactions with operations, capturing leads, managing orders, tracking sales, and supporting service. Combined with reporting and analytics tools, this provides real-time insights for better decisions.

Example: Dell Technologies uses an integrated ERP and CRM to manage direct and B2B sales. Proactive service analytics increased support renewals by 85% and boosted customer satisfaction by 30%+.

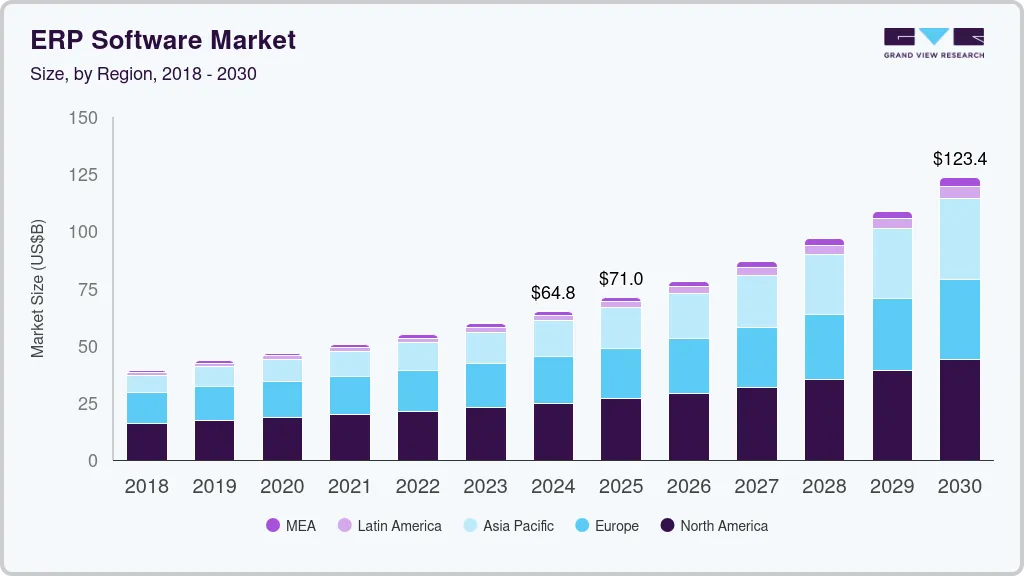

Key Market Takeaways of the ERP Software Industry

The global ERP software market was estimated at USD 64.83 billion in 2024 and is projected to reach USD 123.41 billion by 2030, growing at a CAGR of 11.7% from 2025 to 2030. This growth is fueled by increasing demand for integrated business processes, real-time data insights, and scalable solutions across industries.

Globally, 70% of large enterprises and 43.3% of enterprises in the European Union now use ERP software, with 86.3% of large enterprises using it.

Across industries, 89% of ERP users cite efficiency improvements as a top benefit, and systems have been shown to reduce manual errors by 70%

These are some of the businesses achieving measurable growth through ERP implementation:

- Ronin Gallery (Art & Retail): Implemented NetSuite ERP, which doubled employee productivity, enabling a team of just 4 to manage 50 exhibitions annually.

- N&N Moving Supplies (Distribution & Logistics): Using NetSuite, they reduced their payroll processing time by a remarkable 84%.

- Glider Guard (Manufacturing): Adopted Genius ERP to unify operations, which enabled the company to successfully open a second manufacturing plant.

- Hampton Lumber (Manufacturing): By implementing Epicor ERP, they automated manual processes, improved data accuracy, and achieved savings of approximately $25,000 per year.

Overall, the ERP software market’s rapid growth and widespread adoption highlight its critical role in modern business transformation. Real-world results across industries demonstrate that ERP systems deliver measurable gains in efficiency, accuracy, scalability, and cost savings, reinforcing their value as long-term strategic investments.

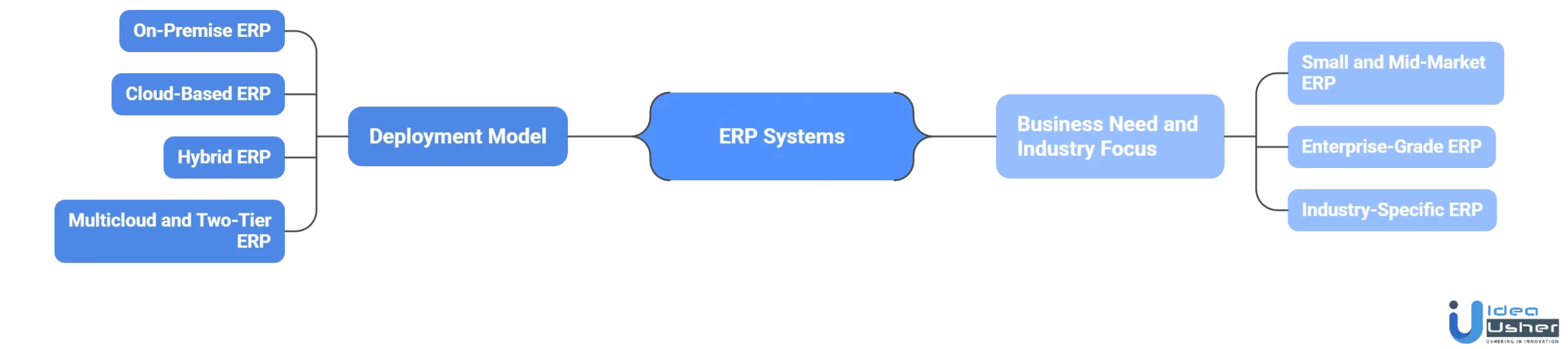

Types of ERP Systems for Business Operations

Selecting the right ERP system is crucial because it determines how effectively your business can unify processes, reduce operational friction, and scale. ERP systems are not one-size-fits-all; they vary based on deployment model, business size requirements, and industry-specific needs. Understanding these variations helps businesses choose an ERP that aligns with their operational goals and technical landscape.

A. ERP Systems by Deployment Model

Deployment type defines where your ERP software is hosted, how it’s maintained, and how users can access it. Different deployment models offer varying levels of control, scalability, cost, and customization.

1. On-Premise ERP Systems

On-premise ERP is installed on your company’s servers and managed by your IT team. It offers maximum control, enhanced data security, and customization for strict compliance needs. However, it requires higher upfront hardware costs and ongoing maintenance.

2. Cloud-Based ERP Systems

Cloud ERP systems are hosted by third-party vendors and accessed via the internet. Also known as Software as a Service (SaaS ERP), this model offers lower upfront costs, automatic updates, and remote accessibility, making it a popular choice for businesses prioritizing flexibility and quick deployment.

3. Hybrid ERP Systems

Hybrid ERP combines elements of both on-premise and cloud solutions. Businesses can keep sensitive or legacy systems on-site while adopting cloud components for flexibility and scalability. This balanced approach is ideal for organizations transitioning from legacy systems or requiring specific data controls.

4. Multicloud and Two-Tier ERP Options

Beyond traditional deployment models, some businesses opt for multicloud ERP, which spreads ERP workloads across multiple cloud environments for resilience and performance, or two-tier ERP, where headquarters use one ERP while subsidiaries run another, enabling tailored operational needs across diverse business units.

B. ERP Systems by Business Need and Industry Focus

In addition to deployment models, ERP systems can also be grouped by how they are tailored to specific business sizes or industry requirements.

1. Small and Mid-Market ERP Systems

These ERP solutions are designed for growing companies that need essential modules like finance, inventory, and CRM without the complexity of full-enterprise suites. They often emphasize affordability, rapid deployment, and ease of use.

2. Enterprise-Grade ERP Solutions

Large corporations with complex operations often require robust systems that support extensive customization, multisite operations, and advanced analytics, alongside broad module coverage. These solutions are built to handle high transaction volumes and global operational requirements.

3. Industry-Specific ERP Systems

Certain ERP systems are tailored to the unique workflows of industries like manufacturing, retail, healthcare, or distribution. These industry-centric systems include preconfigured modules and compliance capabilities that accelerate implementation and drive vertical-specific operational efficiencies.

Cloud vs On-Premise ERP System for Business Operations

Choosing between a cloud or on-premise ERP system for business operations impacts scalability, cost, security, and control. Understanding these differences helps organizations align technology decisions with operational goals and long-term strategy.

| Comparison Factor | Cloud ERP System | On-Premise ERP System |

| Deployment Model | Hosted on cloud infrastructure and accessed via the internet through secure environments. | Installed and operated on the organization’s internal servers and infrastructure. |

| Implementation Speed | Faster deployment due to pre-configured environments and reduced infrastructure setup. | Longer implementation timelines due to hardware provisioning and environment configuration. |

| Upfront Cost Structure | Lower initial investment with subscription-based pricing models. | Higher upfront costs for servers, licenses, and infrastructure setup. |

| Customization Approach | Limited deep customization; favors configuration and standardized workflows. | Supports extensive customization tailored to complex or unique operational requirements. |

| System Maintenance | Vendor-managed updates, patches, and infrastructure maintenance. | Maintenance, updates, and system performance are managed internally. |

| Data Control & Governance | Data is stored in third-party cloud environments with shared responsibility models. | Full control over data storage, security policies, and governance standards. |

| Integration Capability | Strong API-based integrations with modern SaaS tools and cloud platforms. | Integrations often require custom connectors or middleware solutions. |

| Long-Term Cost Considerations | Predictable operational expenses but recurring subscription costs over time. | Higher initial investment but potentially lower long-term recurring costs. |

| Best Fit For | Growing businesses, distributed teams, and organizations prioritizing agility. | Enterprises with complex workflows, strict compliance needs, or legacy infrastructure. |

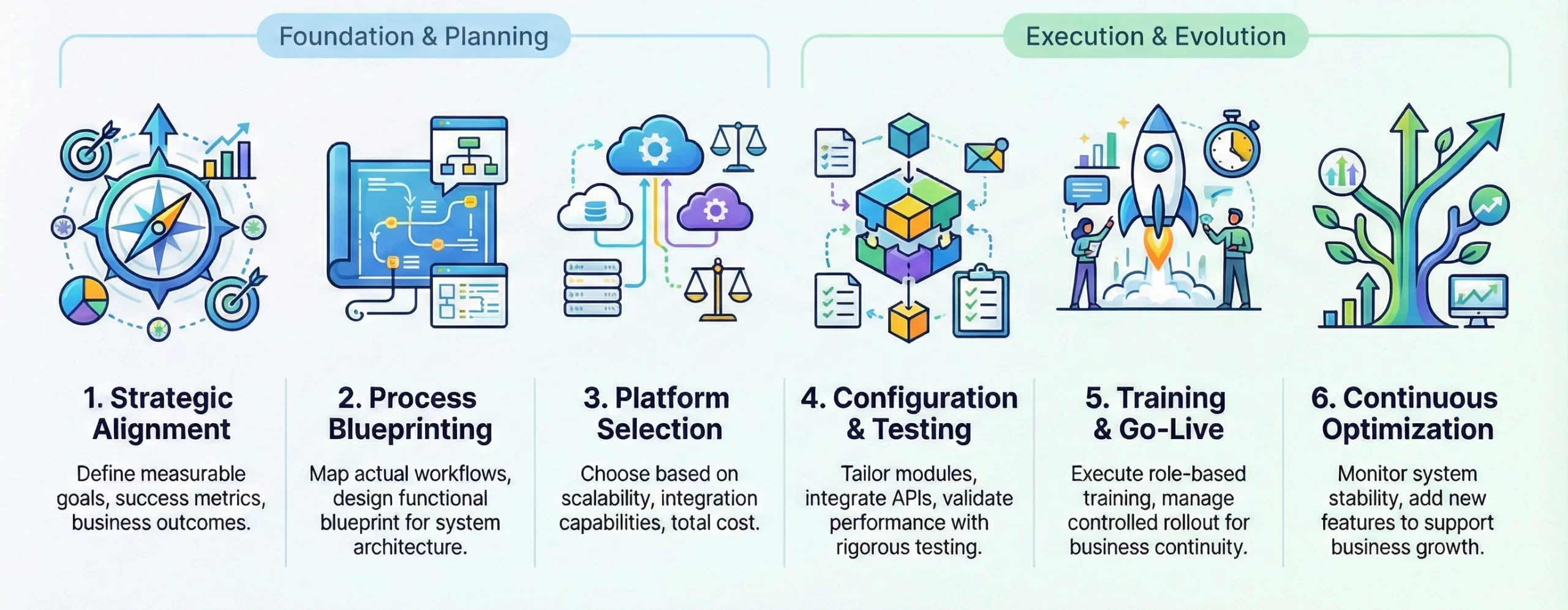

How to Implement an ERP System for Business Operations?

ERP implementation is a structured operational transformation, not just software deployment. It aligns processes, data, and workflows across the organization while creating a scalable foundation through a phased, execution-driven approach tailored to business needs.

1. Align Business Objectives with ERP Strategy

Every ERP implementation starts with strategic alignment. Before choosing modules or platforms, businesses must understand what the ERP system should address such as operational inefficiency, visibility issues, compliance, or scalability.

This phase defines measurable goals, scope, success metrics, and governance to ensure the ERP supports immediate needs and future growth. ERP decisions are driven by business outcomes, not software features.

2. Business Process Analysis and ERP Blueprinting

ERP systems work best when based on actual workflows, not assumptions. Analyzing business processes, documents, workflows in finance, procurement, inventory, HR, and sales, and identifying bottlenecks, redundancies, and manual steps.

Our developers translate this analysis into a functional and technical ERP blueprint, a structured design that defines module configurations, customization boundaries, data flows, and system integrations. This blueprint becomes the foundation for controlled customization and long-term system scalability.

3. Select the Right ERP Platform

Choosing an ERP platform is both technical and strategic. Businesses must evaluate scalability, deployment flexibility (cloud, on-premise, or hybrid), integration, data governance, and total cost of ownership.

Once the platform is selected, system architecture is designed to ensure the ERP integrates seamlessly with existing tools such as CRM platforms, financial systems, supply chain software, and third-party services. A well-planned architecture prevents future performance constraints and ensures reliable data synchronization across systems.

4. Configure, Customize, and Integrate ERP Modules

ERP implementation shifts from planning to execution during configuration and customization. Standard modules are tailored to business rules, approval processes, and reporting. When standard features fall short, controlled customization ensures flexibility while maintaining system stability.

Our developers focus on API-driven and middleware-based integrations, enabling secure, real-time data exchange between ERP modules and external systems. This ensures unified reporting, consistent data integrity, and streamlined end-to-end workflows.

5. Data Migration, Validation, and System Testing

Data migration is one of the most critical and risk-sensitive phases of ERP implementation. Legacy data must be cleansed, standardized, and validated before being transferred into the ERP system to avoid operational disruptions after go-live.

This phase includes structured testing cycles such as unit testing, integration testing, and user acceptance testing (UAT) to validate system performance under real business scenarios. The goal is to ensure the ERP system functions reliably across departments before production deployment.

6. Training, Change Management, and Go-Live

Even the most technically sound ERP system can fail without user adoption. Effective implementation includes role-based training programs, clear documentation, and proactive change management to help teams transition from legacy tools to unified ERP workflows.

Go-live execution is planned either as a phased rollout or a controlled full deployment, depending on operational complexity and risk tolerance. This ensures business continuity while enabling teams to adapt confidently to the new system environment.

7. Post-Implementation Support and Optimization

ERP implementation doesn’t end at deployment. Ongoing monitoring, optimization, and incremental improvements maintain operational value. Businesses often expand ERP use by adding modules, automating workflows, and improving reporting.

Our post-implementation support focuses on system stability, scalability, and continuous improvement, ensuring the ERP evolves alongside business growth rather than becoming another rigid legacy system.

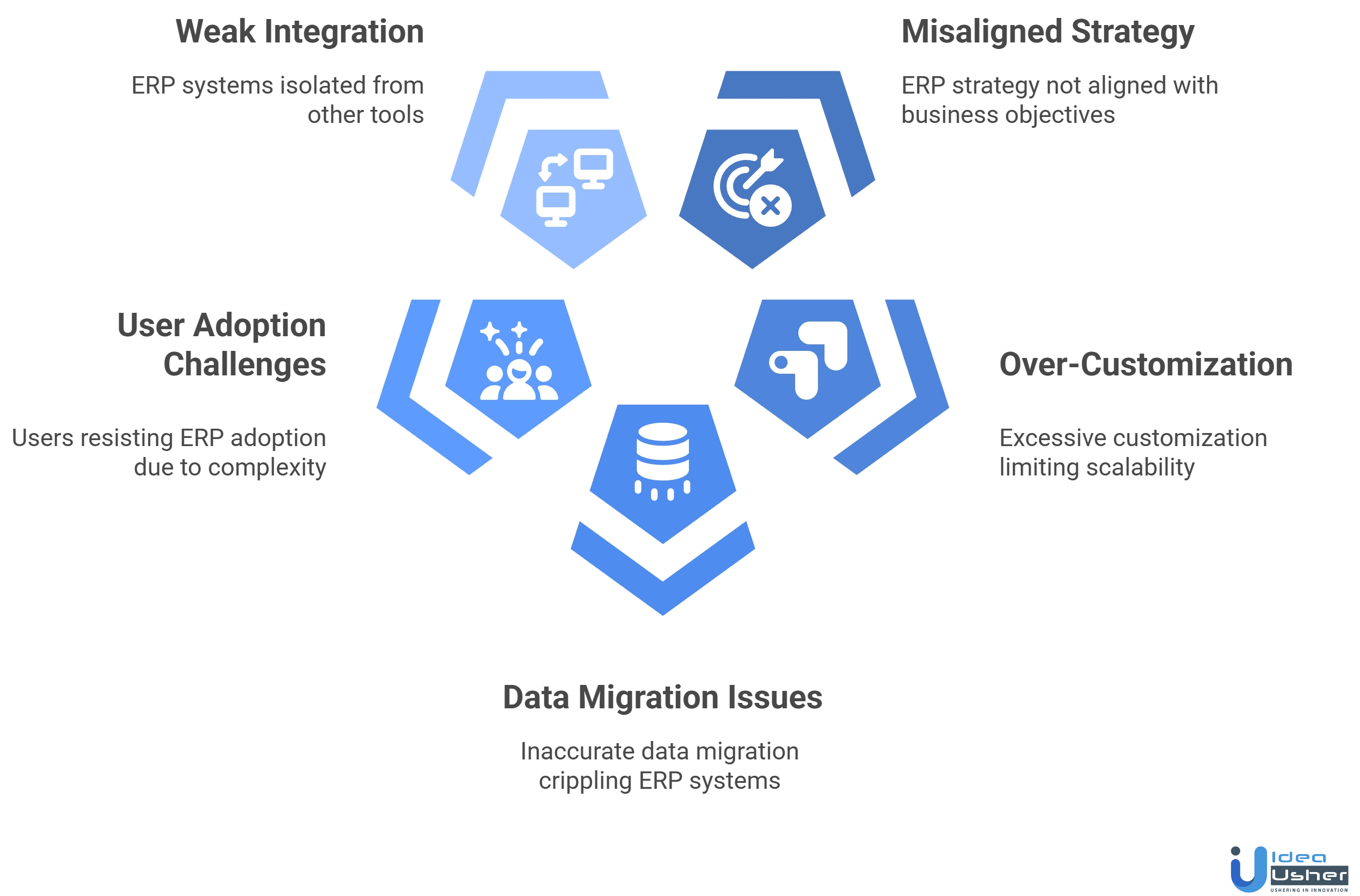

Common ERP Failures & How We Prevent Them?

ERP failures stem from misaligned execution, not weak technology. Issues like unclear requirements, over-customization, and poor adoption are common. Anticipating these risks early helps prevent costly disruptions and supports a successful ERP implementation.

1. Misaligned ERP Strategy

The Failure: Many ERP projects start with software selection instead of clear operational goals. Without alignment to business priorities, organizations often deploy feature-heavy systems that fail to deliver measurable results.

How We Prevent It: We anchor ERP implementation around business-first objectives, not software capabilities. Every module, workflow, and integration is mapped back to defined KPIs such as operational efficiency, reporting accuracy, or scalability, ensuring the ERP supports real business outcomes.

2. Over-Customization

The Failure: Excessive customization often locks businesses into rigid ERP systems that are expensive to maintain and difficult to upgrade. Over time, this creates technical debt and limits the system’s ability to scale.

How We Prevent It: Our developers apply a configuration-first, customization-when-necessary approach. We design ERP systems using modular architecture and extensibility principles, preserving upgrade paths while still supporting business-specific workflows.

3. Data Migration and Quality Issues

The Failure: Inaccurate or incomplete data migration can cripple ERP systems post-launch, leading to reporting errors, operational delays, and user distrust in the system.

How We Prevent It: We treat data migration as a separate engineering discipline, not a checklist task. This includes data audits, cleansing frameworks, validation rules, and parallel testing to ensure data accuracy, consistency, and integrity before go-live.

4. User Adoption Challenges

The Failure: ERP systems fail when poor workflow alignment, complex interfaces, and unclear process changes lead users to rely on legacy tools instead of adopting the system.

How We Prevent It: We reduce adoption friction through workflow-aligned configuration, role-based access control, and intuitive process sequencing, ensuring users transition to ERP through familiar operational patterns rather than forced behavioral change.

5. Weak Integration with Existing Systems

The Failure: ERP systems that operate in isolation from CRMs, analytics platforms, or third-party tools recreate the same data silos they were meant to eliminate.

How We Prevent It: Our ERP implementations follow an integration-first architecture, using APIs and middleware to enable reliable, real-time data exchange. This ensures operational continuity across systems while maintaining a unified data model.

Conclusion

Implementing an ERP system is less about software and more about people, process, and clarity. When goals are defined, stakeholders are involved, and change is managed with care, the transition becomes practical rather than disruptive. Data accuracy, training, and phased execution help reduce risk and build confidence across teams. A well-planned ERP system for business operations ultimately supports informed decisions, consistent workflows, and sustainable growth. With patience and alignment, organizations can turn complexity into structure that genuinely supports everyday work, while keeping accountability visible and collaboration steady throughout implementation.

Why Work with Us for ERP System Implementation?

A successful ERP implementation is as much about process alignment as it is about technology. We help businesses plan, implement, and optimize ERP systems that streamline operations, improve visibility, and support long-term growth.

What Sets Us Apart:

- ERP Strategy & Architecture Expertise: We align ERP capabilities with your business operations, ensuring scalability and operational efficiency.

- End-to-End Implementation Support: From requirement analysis and data migration to integration and post-go-live optimization, our team manages the full ERP lifecycle.

- Industry-Focused Solutions: We tailor ERP implementations to fit unique operational needs across finance, supply chain, HR, and manufacturing.

- Long-Term Value & ROI Focus: Our approach prioritizes system adoption, performance, and measurable business impact.

Take a look at our portfolio to understand our experience in building and transforming enterprise platforms for diverse business needs.

Contact us today for a free consultation and start building an ERP system that supports efficient, connected, and scalable business operations.

Work with Ex-MAANG developers to build next-gen apps schedule your consultation now

FAQs

A.1. Choosing the right ERP starts with evaluating industry fit, scalability, integration capability, and vendor support. The system should align with business complexity and growth plans rather than offering excessive features that slow adoption.

A.2. Critical data includes financial records, customer information, inventory details, and supplier data. Cleansing and validating this data before migration reduces errors, improves reporting accuracy, and prevents operational disruptions after launch.

A.3. Common risks include poor data migration, limited user training, unclear ownership, and rushed timelines. These issues can delay adoption, reduce system accuracy, and impact business continuity if not addressed early.

A.4. Successful adoption requires early stakeholder involvement, role-based training, clear communication, and leadership support. When users understand how the ERP improves daily work, resistance decreases and consistent usage increases.