- Predictive Maintenance Market Size

- What Is Predictive Maintenance Using AI?

- Let's Take A Look At How AI is Boosting Manufacturing Efficiency and Maintenance

- How Does AI In Predictive Maintenance Work?

- Challenges In Traditional Predictive Maintenance Methods

- AI Technologies For Predictive Maintenance

- Conclusion

- Would you like to develop a maintenance system powered by AI?

FAQ

Manufacturing equipment malfunctions can cause hardships for firms. These faults can cause a variety of issues, from delaying output to putting it to a total halt. Fortunately, there is a new approach that can assist in predicting these unexpected failures, and that is AI-enabled predictive maintenance.

Through machine learning (ML) algorithms, AI can analyze vast amounts of data, including historical information and real-time sensor readings, to identify patterns that signal potential equipment issues. This allows companies to take proactive steps to avoid problems before they occur, reducing the risk of costly downtime.

This article will explore the fundamentals of AI in predictive maintenance, along with real-world applications and the key benefits it offers to manufacturers.

- Predictive Maintenance Market Size

- What Is Predictive Maintenance Using AI?

- Let’s Take A Look At How AI is Boosting Manufacturing Efficiency and Maintenance

- How Does AI In Predictive Maintenance Work?

- Challenges In Traditional Predictive Maintenance Methods

- AI Technologies For Predictive Maintenance

- Conclusion

- Would you like to develop a maintenance system powered by AI?

FAQ

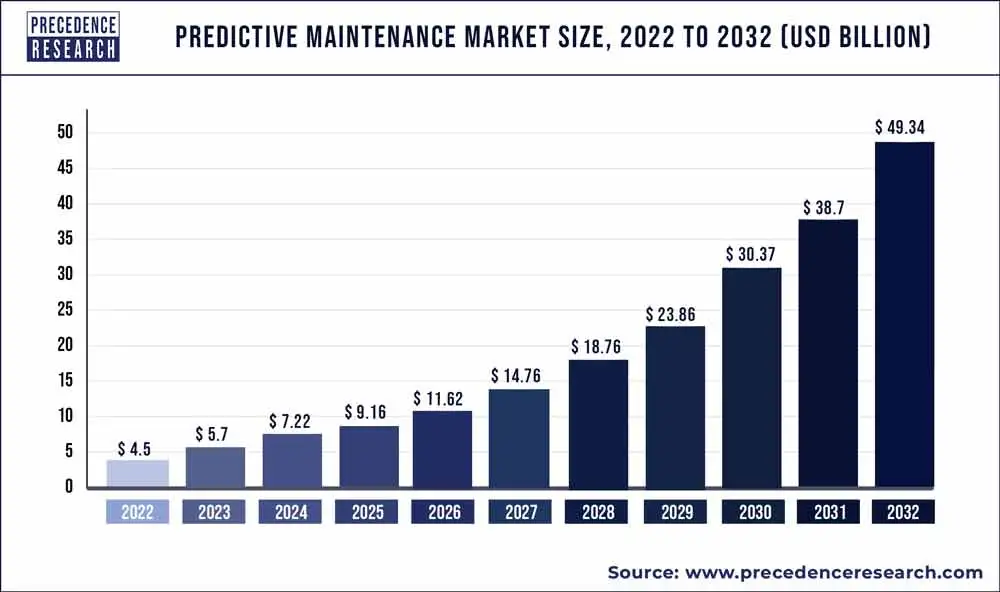

Predictive Maintenance Market Size

Source: Precedenceresearch

Here are some key factors driving this growth such as:

- There is a need to reduce the expenses and downtime caused by unexpected equipment failures.

- The growing use of Internet of Things (IoT) sensors and other technologies for collecting data on equipment health.

- The development of AI and machine learning (ML) systems capable of analyzing this data and forecasting equipment faults.

What Is Predictive Maintenance Using AI?

Imagine a world where your car tells you it needs an oil change before the engine sputters, or your factory machine alerts you to a potential problem before it grinds to a halt. This futuristic scenario is becoming a reality thanks to Artificial Intelligence (AI) and its role in Predictive Maintenance.

In simpler terms, predictive maintenance uses AI to analyze data collected from sensors embedded in equipment to predict when maintenance is needed. This is a significant shift from traditional reactive maintenance, where repairs happen only after a breakdown occurs.

Here’s how AI is revolutionizing maintenance practices:

- Data Analysis Powerhouse: AI algorithms ingest vast amounts of data from sensors monitoring temperature, vibration, and other equipment parameters. By analyzing trends and historical data, AI can identify subtle changes that might signal an impending failure.

- Early Warning Systems: Gone are the days of surprise breakdowns. AI-powered predictive maintenance systems provide early warnings of potential problems, allowing technicians to address them before they escalate into costly downtime.

- Reduced Costs & Increased Efficiency: Predictive maintenance saves money in two ways. First, it prevents major breakdowns that require expensive repairs and replacements. Second, it optimizes maintenance schedules, ensuring resources are directed towards equipment that truly needs attention.

- Improved Machine Performance: By catching problems early, AI helps maintain equipment at optimal performance levels. This translates to increased productivity and overall equipment lifespan.

As AI technology continues to evolve, predictive maintenance will become even more sophisticated. Imagine AI not only predicting failures but also recommending the specific parts or repairs needed. This level of automation will further optimize maintenance processes and revolutionize how we keep our machines running smoothly.

Let’s Take A Look At How AI is Boosting Manufacturing Efficiency and Maintenance

Artificial intelligence (AI) is transforming the manufacturing landscape by offering significant improvements in both production and equipment upkeep. Here’s a closer look at how AI is making a difference:

1. Enhancing Overall Equipment Effectiveness (OEE)

AI tools can analyze entire production processes, identifying bottlenecks and inefficiencies. For instance, AI might uncover a mismatch between two assembly stages, where one produces faster than the other, leading to production loss. Using this data, manufacturers can invest in additional equipment to optimize throughput and achieve better OEE.

2. Facilitating Total Productive Maintenance (TPM)

TPM involves integrating maintenance into overall operations, with participation from all staff members, not just dedicated maintenance teams. AI plays a crucial role here by collecting and readily providing maintenance data to all relevant personnel, empowering everyone to contribute to problem detection and prevention.

3. Optimising Planned Preventative Maintenance (PPM)

PPM involves scheduling routine maintenance tasks to minimize equipment failures. While PPM can be implemented without AI, AI tools can analyze data to pinpoint critical equipment and prioritize maintenance tasks for those areas, ensuring maximum effectiveness.

How Does AI In Predictive Maintenance Work?

Predictive maintenance, powered by AI, is transforming how we keep equipment running smoothly. By analyzing data and identifying patterns, Predictive maintenance with AI is like having a super-powered mechanic constantly monitoring your equipment. Here’s a glimpse into the inner workings:

Data Acquisition

Sensors embedded within machines become the eyes and ears of the system. These sensors collect real-time data on various parameters – vibration, temperature, pressure, current flow, etc. The more data points collected, the better the AI can understand the equipment’s normal operating behavior.

Data Ingestion and Preprocessing

The collected data is fed into the AI system. However, raw data can be messy and incomplete. AI pre-processing techniques clean, organize, and structure the data to prepare it for analysis.

Machine Learning Takes Center Stage

Two main types of machine learning algorithms power predictive maintenance:

- Supervised Learning: Here, historical data plays a crucial role. The AI is trained on past equipment failures and their corresponding sensor readings. By analyzing these patterns, the AI learns to identify similar patterns in real-time data, potentially indicating an upcoming problem.

- Unsupervised Learning: This approach is particularly useful when historical failure data might be limited. The AI analyzes sensor readings to identify anomalies or deviations from the equipment’s typical operating pattern. These anomalies could signal potential issues that require further investigation.

Predictive Modeling and Anomaly Detection

Once the AI has been trained, it creates predictive models that can forecast potential equipment failures. These models continuously analyze incoming sensor data, comparing it to historical patterns and learned anomalies. When significant deviations are detected, the system triggers an alert.

Alerting and Diagnostics

The AI system doesn’t just raise a red flag; it provides valuable insights. Alerts can specify the equipment at risk, the potential issue, and the level of urgency. This empowers maintenance teams to prioritize repairs and take targeted action.

Continuous Improvement

AI is a learning system. As more data is collected and analyzed, the predictive models become more refined and accurate over time. This ongoing learning loop ensures the system continuously adapts and improves its ability to predict potential failures.

Challenges In Traditional Predictive Maintenance Methods

Traditional predictive maintenance methods, while valuable, have limitations that can hinder their effectiveness. Here are several key challenges:

1. Data Dependence on Human Input

Traditional methods often rely on technicians to collect data from equipment inspections, such as vibration readings or temperature measurements. This dependence on human expertise introduces the risk of inconsistency and errors. Variations in how inspections are conducted or data is interpreted can significantly impact the accuracy of predictions.

2. Limited Data Scope

Traditional methods typically gather data from a limited set of parameters during inspections. These parameters might focus on easily measurable aspects like temperature or lubrication levels. However, this limited scope can miss crucial early warning signs of equipment degradation. For instance, traditional inspections might not capture subtle changes in a current draw that could indicate developing problems with a motor.

3. Data Overload

With the increasing complexity of modern equipment, traditional methods can generate a surge of data points during inspections. Analyzing this data manually can be overwhelming for maintenance teams, leading to information overload and missed critical equipment failures. The sheer volume of data points can make it difficult to identify the key indicators that require immediate attention.

4. High Initial Investment

Implementing a comprehensive predictive maintenance program often requires investing in sensor technology and data analysis tools. These upfront costs can be significant, especially for smaller organizations or those with limited budgets. While the long-term benefits of increased efficiency and reduced downtime can outweigh the initial investment, securing the initial funding can be a hurdle.

5. Data Management Complexity

The vast amounts of data collected by sensors can be complex to manage and store. Traditional IT infrastructure might not be equipped to handle the scale and real-time nature of this data. Organizations may need to invest in additional storage capacity or cloud-based solutions, along with expertise in data management, to ensure the information is readily available for analysis.

6. Change Management Hurdles

Transitioning from traditional, routine inspections to a data-driven predictive maintenance approach can face resistance from personnel accustomed to established workflows. Technicians who are comfortable with their current roles might be apprehensive about adopting new technologies or data analysis procedures. Effective communication and training programs are crucial to overcoming these hurdles and ensuring the successful adoption of the new approach.

7. Data Security Concerns

Storing and transmitting sensitive equipment data raises concerns about data breaches and unauthorized access. This data can be valuable for industrial espionage or sabotage. Implementing robust data security protocols, such as encryption and access controls, is essential to protect sensitive information and maintain operational integrity.

AI Technologies For Predictive Maintenance

AI technologies are at the cutting edge of predictive maintenance, allowing enterprises to manage assets more effectively and reduce downtime. Here are some significant artificial intelligence technologies utilized in predictive maintenance:

1. Machine Learning (ML)

The foundation of predictive maintenance is that ML algorithms like decision trees and support vector machines (SVMs) analyze historical sensor readings and equipment performance to identify patterns and relationships. By learning from this data, ML models can predict when maintenance is likely needed, allowing organizations to address issues before they escalate into failures.

2. Deep Learning

Deep learning excels at processing complex, high-dimensional data, making it a powerful tool for anticipating equipment failures and optimizing maintenance strategies. One key application is anomaly detection. Deep learning models like autoencoders and recurrent neural networks (RNNs) are adept at recognizing subtle deviations from normal equipment behavior, providing early warnings of potential problems.

3. Natural Language Processing (NLP)

An emerging technology in predictive maintenance, NLP offers new ways to manage textual data and improve maintenance strategies. NLP enables machines to understand and generate human language, making it useful for extracting insights from maintenance reports, equipment manuals, and technician notes. A key application of NLP is information extraction.

4. Computer Vision

Computer vision plays a crucial role by providing the ability to inspect equipment and identify potential issues visually. Cameras, image processing algorithms, and deep learning techniques are used to interpret and analyze visual data from industrial machinery. Visual inspection is a key application. Cameras and sensors strategically placed on equipment capture real-time visual data.

Conclusion

AI-powered predictive maintenance is revolutionizing how industries manage assets. It’s not just a tool; it’s a game-changer. By proactively monitoring equipment, AI predicts breakdowns, reduces maintenance costs, and optimizes resources.

AI-powered predictive maintenance looks beneficial, but it has certain challenges. For example, data collecting necessitates the installation of sensors and their integration into existing systems. Then, there’s training the AI, which requires a lot of specialized equipment and data.

Partnering with an AI development company can help businesses overcome these obstacles. These professionals can build the system, collect the necessary data, and train the AI to anticipate equipment failures, saving you money and downtime.

Would you like to develop a maintenance system powered by AI?

As an AI development company, we can revolutionize your maintenance needs with cutting-edge AI solutions. Our expertise lies in building robust machine-learning models that analyze sensor data, historical trends, and equipment specifications.

We’ll work closely with your engineers to understand your specific needs and deploy a seamless AI integration, optimizing maintenance schedules, minimizing downtime, and maximizing equipment lifespan.

Contact us to learn more about how we can help you with our AI development services.

FAQ

Q. How can predictive maintenance with AI benefit businesses?

A. Predictive maintenance with AI can revolutionize your business by enabling you to anticipate equipment failures before they happen. This translates to reduced downtime, lower maintenance costs, and optimized operations. AI can analyze vast amounts of data to identify patterns and predict potential failures with high accuracy. This allows you to take proactive steps to prevent problems before they escalate.

Q. Is predictive maintenance with AI suitable for different industries?

A. The benefits of AI-powered predictive maintenance extend across industries. Whether you’re in manufacturing, transportation, energy, or any other sector that relies on machinery, this technology can streamline operations, improve reliability, and cut costs.

Q. What are the implementation challenges of adopting AI for predictive maintenance?

A. There are some challenges to implementing AI for predictive maintenance. These include integrating data from various sources, ensuring data quality, and establishing communication channels between AI systems and maintenance teams. However, with proper planning and expertise, these challenges can be overcome.

Q. How does predictive maintenance impact overall business profitability?

A. The impact of predictive maintenance on your bottom line is significant. By minimizing downtime, reducing maintenance costs, and optimizing resource utilization, it directly contributes to improved profitability. Additionally, you can schedule maintenance during off-peak hours and prevent costly equipment failures, leading to higher revenue and increased customer satisfaction.

Gaurav Patil