The incorporation of Artificial Intelligence (AI) in the food industry has brought about a revolutionary shift in how we produce, distribute, and consume food. AI technologies such as machine learning, data analytics, and computer vision are reshaping traditional agricultural practices, optimizing supply chain logistics, and elevating food safety standards.

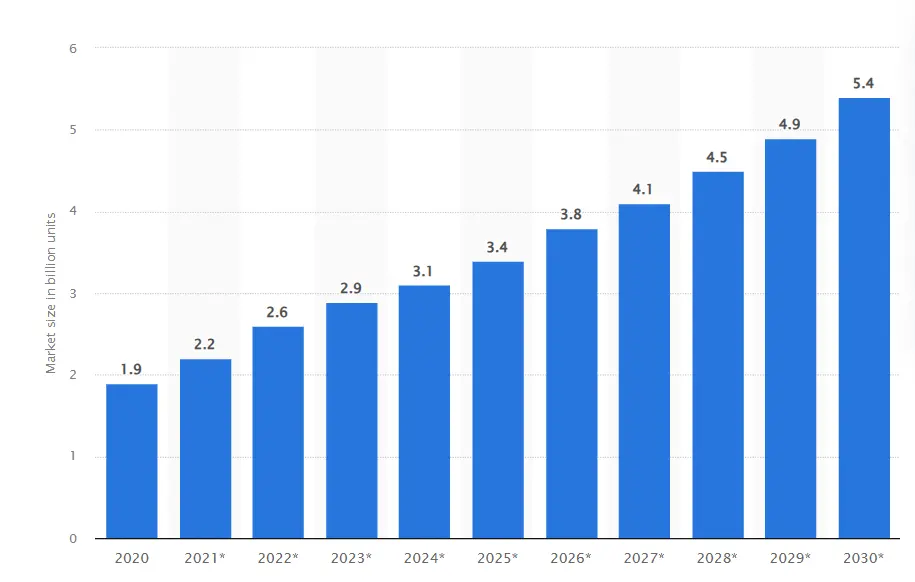

Source: Statista

This emphasizes the importance of AI and robots in influencing the future of the food industry, supporting innovation, efficiency, and sustainability.AI has a wide-ranging impact on the food ecosystem, from precision farming and crop production prediction to tailored nutrition and intelligent food delivery.

This blog aims to provide an insight about the significant impact of AI on the food business, examining its potential to address global concerns, improve sustainability, and fulfill customers’ dynamic expectations in a rapidly changing world.

Business Benefits Of AI Automation In The Food Industry

Explore the diverse advantages that AI brings to the food sector, propelling businesses toward a more technologically advanced and competitive future.

1. Enhanced Operational Efficiency

The integration of AI has revolutionized operational efficiency in the food industry. Automated systems powered by AI execute food processing tasks precisely, significantly boosting productivity and allowing for continuous, 24/7 operations. Artificial intelligence plays a pivotal role in identifying issues such as lapses in food protection measures, human errors, and other factors that impact food quality, contributing to a more streamlined and error-free production environment.

The increased efficiency accelerates production and ensures the consistency and quality of food products, meeting the stringent standards demanded by the industry and consumers alike.

2. Data-Driven Decision Making

Embracing data enrichment tools, the food and beverage industry leverages AI to facilitate informed decision-making. By navigating intricate industry databases, businesses extract actionable insights, enabling strategic choices for enhanced operational efficiency and market responsiveness.

Implementing AI in data-driven decision-making ensures that food manufacturers and distributors stay ahead in a dynamic market, addressing challenges proactively and optimizing their processes for maximum effectiveness.

3. Sustainability

AI is pivotal in making the food industry more sustainable than ever. AI significantly reduces food waste by accurately predicting demand and optimizing inventory levels. The technology facilitates precision farming in agriculture by providing real-time data on crop health and soil conditions, optimizing yields, and promoting sustainable farming practices.

The adoption of AI-driven technologies in agriculture and supply chain management ensures economic viability for businesses and contributes to broader sustainability goals, addressing environmental concerns and fostering responsible practices within the industry.

4. Improved Customer Engagement

AI has elevated customer engagement in the entire food industry. Through advanced analysis of customer behavior and preferences, AI delivers personalized recommendations, enhancing individualized experiences and fostering customer loyalty for food businesses. This personalized approach to customer interaction creates a more tailored and satisfactory dining or purchasing experience.

Understanding and catering to individual preferences helps food businesses build stronger connections with their customers, ultimately translating into increased customer satisfaction and loyalty.

How Are AI And Robotics Automation Changing The Food Industry?

AI and robotics are revolutionizing the food industry, reshaping production, distribution, and consumption practices to foster innovation, efficiency, and sustainability in an ever-evolving landscape.

1. Agriculture

Agriculture is witnessing a profound transformation driven by AI and robotics. Precision agriculture, powered by AI-driven drones and robots equipped with advanced sensors, is revolutionizing crop monitoring. These technologies enable real-time assessment of soil conditions, water usage, and crop health. Machine learning algorithms analyze data to optimize planting schedules, predict yields, and detect diseases early on, contributing to efficient agricultural management and reduced waste. Automated farm equipment, guided by AI, ensures precise planting, harvesting, and weeding, addressing the challenges posed by a rapidly expanding global population and enhancing food security and sustainable resource management.

2. Culinary Transformation

The culinary landscape is experiencing a transformation with the integration of robots. Restaurants are increasingly adopting cutting-edge robotic technology for food preparation and cooking. These versatile machines handle various tasks, from chopping and roasting to garnishing final dishes. The efficiency of robotic cooks presents the potential to replace low-paid workers in kitchens, catering to the growing demand for innovative and efficient cooking solutions. While robotic cooking and delivery are still in their early stages, the demand for these technologies is on the rise.

3. Automated Food Delivery

The trend of automated food delivery, driven by AI solutions, addresses the increasing demand for ready-to-eat food items. While the adoption of autonomous delivery methods is debatable, the influence of our inclination towards ordering food is undeniable. Stakeholders in the food industry are exploring options like drone delivery, overcoming challenges to revolutionize the delivery process and meet consumer expectations.

4. Autonomous Food Manufacturing

AI and robotics play a pivotal role in autonomous food manufacturing, addressing the escalating demand for food. This involves various stages, including packing and safety training, performed within production facilities. Robots are employed for cleaning, categorizing, and sorting different types of food. For instance, robotic systems efficiently categorize fruits and vegetables into different containers, enhancing the overall manufacturing process. Robotics automation allows the customization of cutting devices for slicing fruits and vegetables, ensuring efficiency and quick processing. These robots find applications not only in production facilities but also independently in supermarkets for cutting and cooking.

5. Food Packaging with Robotics

Post-manufacturing, the integration of robotics in food processing significantly impacts packaging. AI-powered robotic systems assemble components for packaged meals, such as frozen meals, meeting market demands efficiently. These robots also contribute to organizing and packaging food in boxes for storage and shipment, streamlining store operations. The use of robotics in the packaging process not only enhances efficiency but also presents a unique opportunity to reduce waste through optimized automation.

6. Supply Chain Administration

AI is significantly enhancing supply chain management in the food industry. This technology contributes to:

- Food standards surveillance

- Product testing at each level

- Accurate inventory management

- Tracking products from harvest to distribution

- Ensuring staff adherence to basic hygiene standards

By utilizing cameras, facial recognition, and object-recognition software, AI ensures compliance with food safety standards in both manufacturing facilities and restaurants. This technology plays a vital role in maintaining top-notch hygiene and food quality standards.

7. Creation of New Products

AI’s strategic role in analyzing the market enables food manufacturers to create products aligned with consumer demands. By applying algorithms to identify food sector trends and predict their growth, AI assists in predicting consumer tastes and patterns. This predictive analytics aids in creating new items tailored to the interests of the target market, reducing the rejection rate of new products and ensuring industry leadership.

8. Food Sorting Options

AI and robotics contribute to efficient food sorting by enhancing automation and intelligence. AI systems analyze photos and sensor data to identify flaws, sizes, and quality of food items. Precision actuator-equipped robotics sort and separate products based on predetermined parameters, ensuring quick and reliable sorting. This combination minimizes human error and lowers labor expenses, upholding quality standards and improving supply chain effectiveness, ultimately providing consumers with fresher and safer goods.

Use Cases Of AI & ML In Food Industry

AI and machine learning are offer diverse applications within the food industry, with various food companies leveraging these technologies for specific purposes.

1. Coca-Cola

Coca-Cola leverages AI and ML algorithms to enhance its distribution and supply chain processes. The company can precisely forecast demand by employing advanced technology, ensuring that products are available when and where needed. This minimizes stockouts and reduces surplus inventory, leading to a more efficient and streamlined supply chain. Implementing AI in distribution allows Coca-Cola to optimize its operations and meet customer demands more effectively

2. Nestlé

Nestlé harnesses the power of AI to drive innovation in product development. AI-powered platforms analyze market data, monitor social media trends, and gather customer input to identify emerging food trends. By understanding consumer preferences and market demands, Nestlé can create and improve products that align with the evolving needs of its target audience. This strategic use of AI positions Nestlé as an industry leader in developing goods that cater to changing consumer tastes

3. Beyond Meat

Beyond Meat, a leading plant-based food company integrates AI and ML to improve the flavor and texture of its meat alternatives continually. The company refines its products by analyzing sensory data, user feedback, and ingredient profiles. This application of AI allows Beyond Meat to stay at the forefront of innovation, meeting consumer expectations for high-quality plant-based alternatives in taste and texture

4. Starbucks

Starbucks utilizes AI-driven personalization to elevate customer experiences through its mobile app. The app analyzes a customer’s past orders, preferences, and location information to recommend tailored food and drink. This level of personalization enhances customer satisfaction and engagement, showcasing how AI can be harnessed to create a more individualized and enjoyable experience for Starbucks patrons.

Trends in Automation and AI in Food Industry

From Internet of Things (IoT) integration to machine learning and predictive analytics, and the rising influence of robotics and cobots, discover how these technological advancements are reshaping the future of food processing.

1. Internet of Things (IoT) Integration

The integration of IoT in food processing is a transformative trend. IoT devices, such as sensors and connected equipment, play a crucial role in gathering real-time data in food processing plants. This real-time data is invaluable for process monitoring, ensuring product quality, and facilitating predictive maintenance. The synergy of IoT with automation and AI allows for enhanced decision-making based on data-driven insights. This integration not only optimizes operational efficiency but also contributes to sustainable and resource-efficient food processing practices.

2. Machine Learning and Predictive Analytics

The deployment of machine learning algorithms in food processing is revolutionizing various aspects of the industry. These algorithms analyze large datasets, enabling accurate predictions in critical areas like demand forecasting, quality control, and supply chain optimization. Predictive analytics empower manufacturers to make informed decisions, reduce costs, and enhance operational efficiency. By leveraging machine learning, the food processing industry can respond dynamically to market demands, ensuring optimal production and minimizing waste.

3. Robotics and Cobots

The adoption of robotics and collaborative robots (cobots) is gaining momentum, reshaping the food processing landscape. Robots and cobots work alongside human workers, particularly in repetitive or physically demanding tasks. Their ease of programming and reconfiguration offers unparalleled flexibility, swiftly adapting to changing production requirements. This trend not only enhances efficiency but also contributes to a safer and more ergonomic working environment, combining the strengths of human expertise with the precision and consistency of automation.

Top Examples Of Food Apps Using AI

From personalized recipe recommendations to advanced cooking assistance, the following apps seamlessly integrate AI to elevate our food experiences.

1. Yelp

Yelp leverages AI to elevate the restaurant discovery experience for users. The platform personalizes recommendations by analyzing individual reviews, ratings, and location data. By understanding user preferences and behavior, Yelp’s AI enhances the accuracy of suggested restaurants, creating a tailored dining experience. Furthermore, Yelp’s AI capabilities extend to analyzing user reviews to identify trends, offering valuable insights into potential allergens or dietary restrictions. This not only improves user engagement but also enhances the overall safety and satisfaction of the dining experience.

2. Grubhub

Grubhub integrates AI into its platform to enhance user engagement and streamline the food ordering process. The AI predicts user preferences based on past behavior, suggesting similar dishes to enhance the overall dining experience. Additionally, Grubhub employs AI for personalized deals and promotions, creating a targeted and appealing offering for individual users. Through these AI-driven features, Grubhub aims to provide a seamless and personalized food ordering experience that aligns with the unique tastes and preferences of its users.

3. Uber Eats

Uber Eats utilizes AI to optimize various aspects of its food delivery service. The platform employs AI algorithms to enhance delivery route optimization, predict accurate delivery times, and offer personalized restaurant recommendations. By analyzing user data, location information, and even considering weather conditions, Uber Eats aims to provide a highly tailored and efficient food delivery service. The integration of AI into the platform contributes to an improved overall user experience, making food delivery more convenient and personalized.

4. Food AI by Samsung

Samsung’s Food AI app focuses on enhancing the culinary experience by learning and adapting to user preferences. The app uses AI to suggest recipes based on individual tastes, dietary restrictions, and available ingredients. This personalized approach not only simplifies the cooking process but also promotes healthier and more enjoyable eating habits. The ability of the app to adapt recipes based on user-specific constraints adds a layer of flexibility, making it a valuable tool for individuals with diverse dietary needs.

5. Pepperplate

Pepperplate employs AI to offer personalized meal plans based on users’ dietary needs, preferences, and health goals. The app goes beyond mere recipe recommendations by providing step-by-step cooking instructions with video tutorials. By utilizing AI to generate tailored meal plans, Pepperplate aims to simplify the meal preparation process, making it more accessible and enjoyable for users with varying levels of culinary expertise.

6. Recipe AI

Recipe AI stands out by helping users discover recipes based on the ingredients they have on hand. By leveraging AI, the app goes a step further, generating new recipes by combining different ingredients and flavors. This innovative approach not only inspires creativity in the kitchen but also addresses the challenge of making delicious meals with the items available at home. Recipe AI’s use of AI-driven recipe generation contributes to a more dynamic and personalized cooking experience for users.

7. Too Good To Go

Addressing the issue of food waste, Too Good To Go partners with restaurants and grocery stores to sell surplus food at discounted prices. The app employs AI to predict potential food waste and efficiently match it with interested buyers. This not only benefits consumers by providing affordable meals but also contributes to sustainability efforts by reducing unnecessary food disposal. Through the integration of AI, Too Good To Go plays a vital role in creating a more sustainable and conscious approach to food consumption.

8. Olio

Olio focuses on food sharing and waste reduction by connecting users who have surplus food with those in need. AI is employed to facilitate this matchmaking process efficiently. By understanding user preferences, availability, and location, Olio’s AI ensures that excess food finds its way to individuals who can benefit from it. This AI-driven approach contributes to a community-centric and sustainable solution, reducing food waste and promoting a sense of shared responsibility for resource conservation.

Existing Automation Challenges In The Food Industry

The food industry is undergoing transformative challenges driven by shifts in consumer demand and the imperative for sustainable practices. This list section delves into key challenges faced by the food industry,

1. High Costs and Time Constraints in Routine Activities

The food industry grapples with the high costs and time constraints associated with manual completion of routine activities. This not only burdens businesses economically but also stifles innovation. The implementation of robotics and automation technologies offers a viable solution to this challenge. Automated processes can significantly reduce both time and costs, allowing businesses to reallocate resources towards innovation and addressing other critical aspects of the industry. This shift towards automation enhances efficiency and competitiveness in the market.

2. Disruptions in the Demand-Supply Relationship

Frequent disruptions in the demand-supply relationship, driven by a narrow production tolerance, pose a significant challenge to the expansion of the food industry. Traditional methods of production struggle to adapt swiftly to fluctuations in demand, resulting in inefficiencies and potential revenue loss. The integration of robotics and automation enables a more agile response to changing market demands. Automated systems can adjust production levels rapidly, ensuring a more seamless and responsive supply chain. This adaptability is crucial for businesses seeking sustainable growth in the dynamic food industry landscape.

3. Challenges in Data Gathering and Decision-Making

Conventional methods in the food industry face challenges in data gathering, market insights, and monitoring consumer trends. The lack of efficient data-driven decision-making processes hinders the industry’s ability to respond quickly to market changes. Robotics and automation technologies offer solutions by providing real-time data analytics. Automated systems can gather, analyze, and interpret data, empowering businesses with valuable insights. This, in turn, facilitates informed decision-making, streamlining operations, and optimizing the revenue model.

4. Margin of Error in Non-Automated Food Production

Food production firms without automation often face a wider margin of error due to human processing and a lack of controls. Human errors in manual processes can lead to quality issues, safety concerns, and inconsistencies in production. The adoption of robotics and automation ensures precision, reducing the margin of error significantly. Automated systems follow predefined controls, enhancing quality assurance and compliance with industry standards. This not only improves overall product quality but also contributes to the safety and reliability of food products

Cost-Affecting Factors To Consider For Integrating AI Automation in Food Industry

When considering AI integration in the food business, a number of cost-related variables must be addressed. This includes:

1. Technology Infrastructure Costs

Implementing AI in the food industry demands a robust technological foundation. The initial investment includes acquiring cutting-edge hardware, specialized software, and establishing a sophisticated networking infrastructure. High-performance servers, GPUs for accelerated processing, and advanced AI development platforms contribute to the overall technology infrastructure costs. The choice between on-premise and cloud-based solutions also influences expenditures, with cloud options offering flexibility but potentially incurring recurring expenses based on usage.

2. Data Collection and Storage

AI systems heavily rely on quality and diverse datasets for training and continuous learning. The cost of data collection involves acquiring relevant information from various sources, which may include purchasing datasets, implementing sensors, or collaborating with external data providers. Additionally, the expenses associated with processing and storing large volumes of data cannot be overlooked. This encompasses investing in secure and scalable storage solutions, as well as data preprocessing tools to ensure the quality and readiness of the data for AI applications.

3. Training and Skill Development

Building and maintaining AI solutions require a skilled workforce. The cost of training personnel in AI technologies, machine learning algorithms, and data science methodologies is a significant consideration. This involves not only formal education or workshops but also ongoing skill development to keep the team abreast of the latest advancements in AI. Alternatively, hiring experienced AI professionals adds to the personnel costs, necessitating a balance between upskilling existing staff and recruiting specialized talent.

4. Customization and Integration

Tailoring AI systems to the specific needs of the food industry involves customization and seamless integration into existing workflows. This may require adapting AI algorithms to suit the nuances of food production, supply chain management, or quality control. The complexity of integration varies, influencing the costs associated with software development, system testing, and ensuring interoperability with existing technologies. Investing in user training to facilitate a smooth transition also contributes to customization expenses.

5. Regulatory Compliance

Adhering to industry regulations and standards is paramount in AI implementation within the food sector. Costs associated with legal consultations to ensure compliance, implementing robust data security measures to safeguard sensitive information, and incorporating ethical guidelines into AI algorithms contribute to regulatory compliance expenses. Investing in transparency measures and audits may be necessary to demonstrate alignment with regulatory requirements and build trust among stakeholders.

6. Maintenance and Upgrades

Ensuring the ongoing optimal performance of AI systems involves continuous maintenance, updates, and periodic upgrades. The associated costs include monitoring system health, addressing bugs or issues, and implementing security patches. Planning for regular software updates to incorporate the latest advancements in AI technology is essential. Additionally, budgeting for hardware upgrades or replacements to accommodate evolving requirements contributes to the long-term sustainability of AI applications.

7. Scalability

Anticipating future growth and ensuring that AI solutions can scale with increasing demands is a critical consideration. Scalability involves both horizontal scaling, accommodating a growing volume of data and users, and vertical scaling, enhancing the system’s capabilities. Initial investments in scalable infrastructure, flexible licensing agreements, and modular development practices contribute to scalability. Planning for potential increases in computational and storage needs as the business expands helps manage long-term costs effectively.

Conclusion

From precision farming to supply chain optimization and personalized consumer experiences, AI has become a catalyst for efficiency, innovation, and sustainability. As the global demand for smarter, more streamlined food production continues to grow, businesses in the food industry must recognize the imperative of integrating AI technologies into their operations to stay competitive.

However, navigating the complexities of AI implementation requires specialized knowledge and expertise. Collaborating with a reputable AI development company can prove instrumental in unlocking the full potential of AI for your business.

By partnering with experts, businesses can benefit from customized AI applications, ensuring seamless integration, optimal performance, and the ability to adapt to evolving industry needs.

How Can Idea Usher Help Your Business With AI Solutions?

At Idea Usher, we are inspired by the changing environment of AI-based solutions across several industrial sectors. Recognizing the revolutionary potential of AI and robots in process automation, our development team is skilled at using these technologies to help your organization succeed.

Whether you own a restaurant chain or want to develop a bespoke on-demand food delivery service to fulfill the rising demand in your area, strategic and long-term partnership is crucial.

We assure a world-class output based on our considerable knowledge from numerous mobile app development projects. Beyond creating a flawless user experience, we are committed to efficiently addressing market requirements.

Consider collaborating with Idea Usher now for clear two-way communication throughout the development process and on-time product delivery!

Work with Ex-MAANG developers to build next-gen apps schedule your consultation now

FAQ

Q. Why automation is important in the food industry?

A. Automation is vital in the food industry to effectively tackle existing challenges. The integration of AI-based systems and robotics reduces error margins, enhances production efficiency, organizes data for informed decision-making, and automates repetitive tasks, unlocking the industry’s full potential.

Q. What is the role of robotics in the food industry?

A. Robotics plays a pivotal role in various facets of the food industry, streamlining cultivation processes through mechanization, systematically sorting raw materials into finished products, ensuring adherence to safety standards, and optimizing packaging procedures.

Q. How is AI used in the food industry?

A. AI finds application in diverse areas of the food industry, including food processing and packaging, ensuring food safety and efficient waste management, and conducting revenue analysis for strategic decision-making.

Q. How do you automate a food business?

A. Automation of a food business involves leveraging robotics and AI technologies at multiple levels, encompassing manufacturing and packaging processes, optimizing food ordering systems, standardizing safety protocols, efficiently managing inventory, and conducting cost-benefit analyses.